Ordnance Survey has been involved in producing paper maps since the early days although the methods have changed considerably. This originally used copperplate engraving but by the time Ordnance Survey decided to outsource this, it was a high tech operation with new printing presses and other equipment.

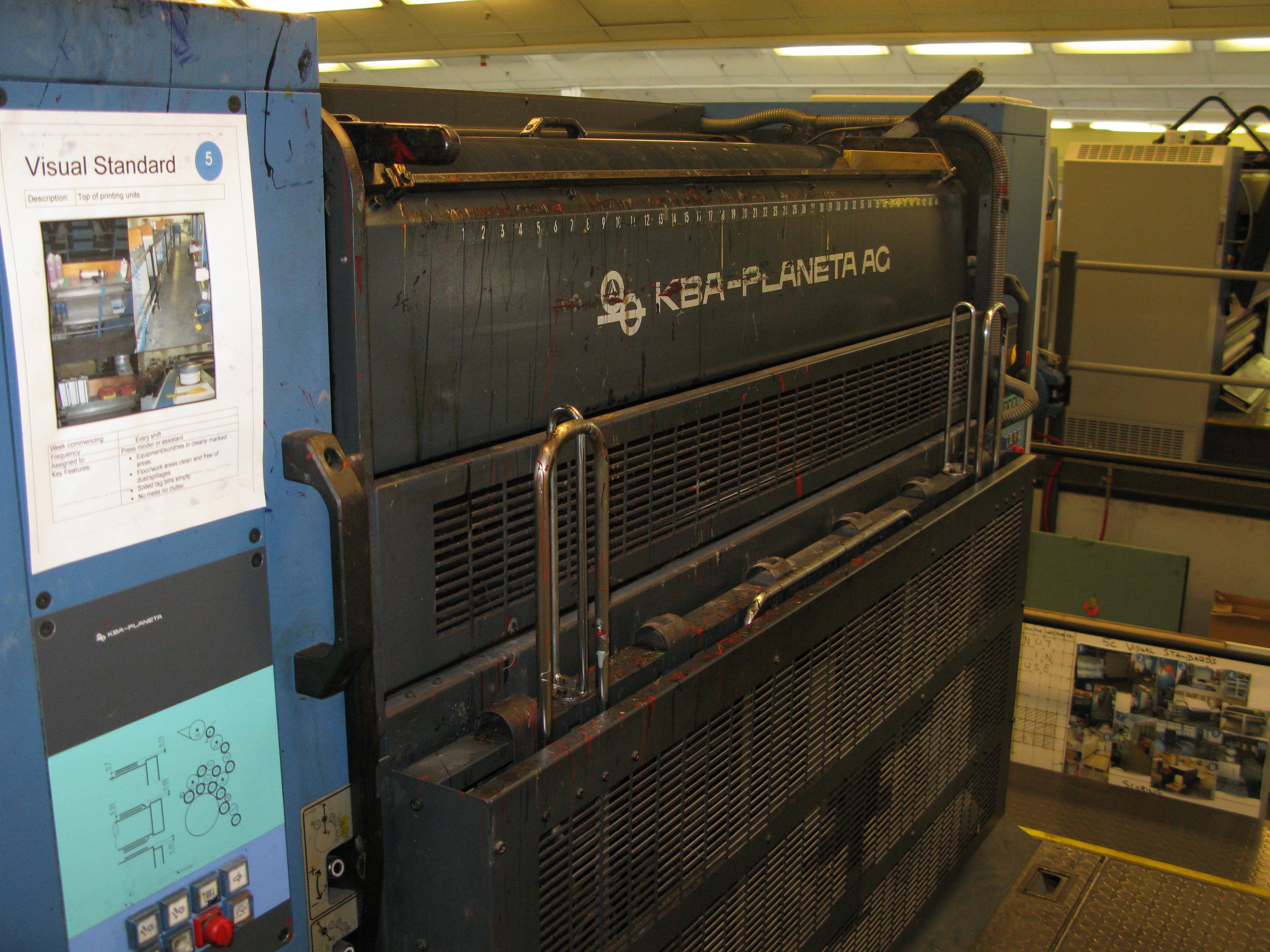

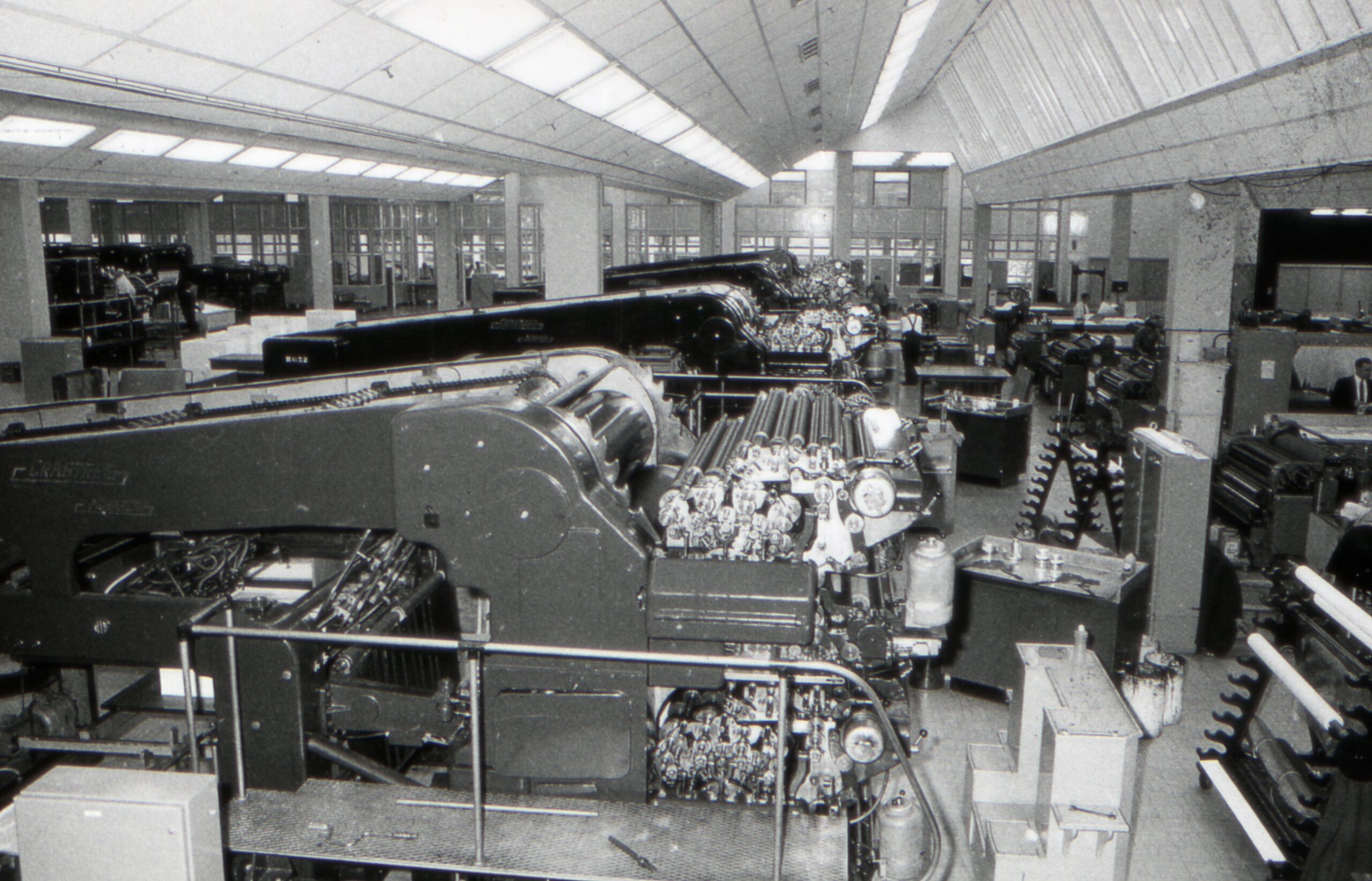

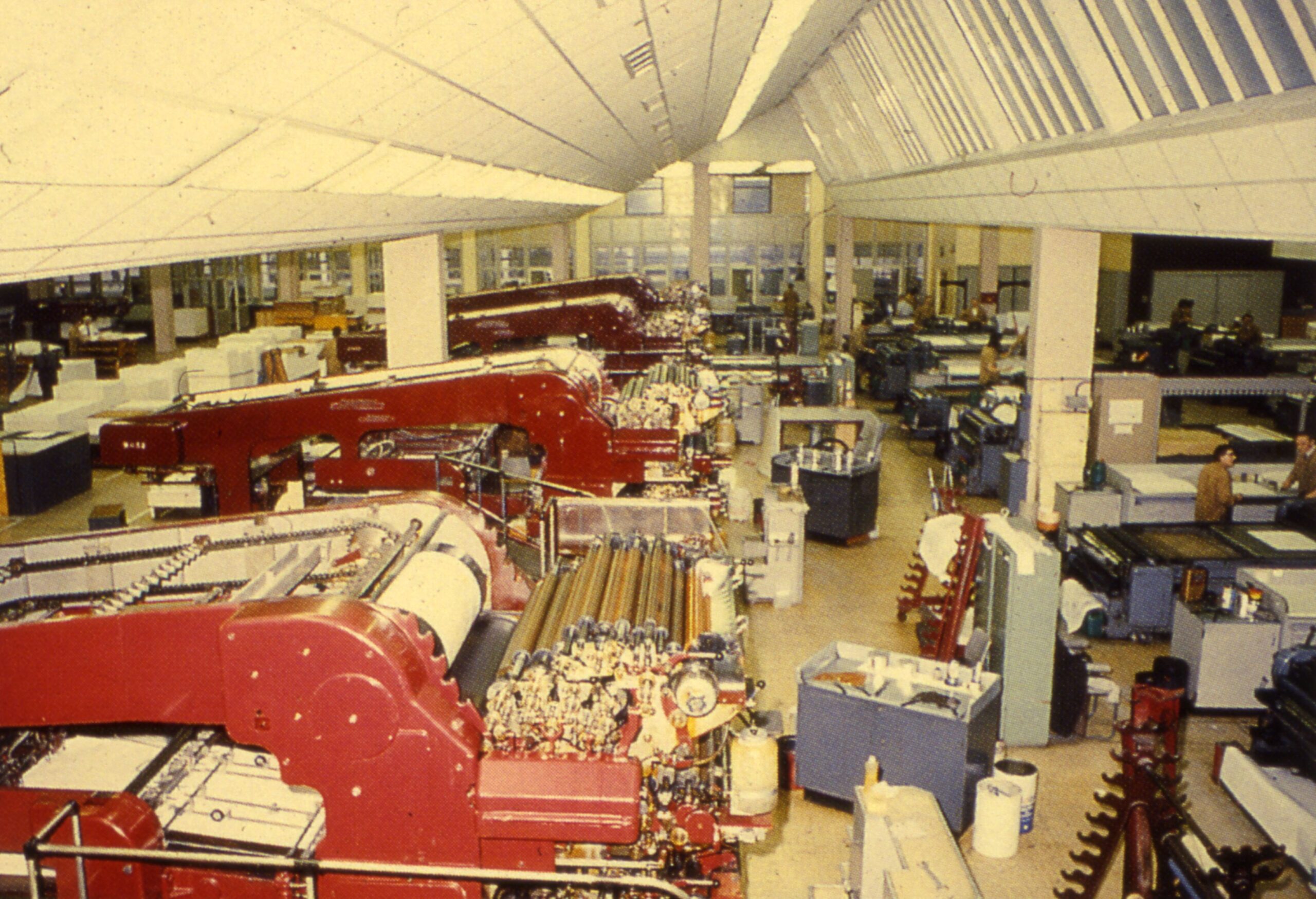

The Print Floor was located on the ground floor of the William Roy Building (WRB), to the NE side. The front end was originally used for ‘proving’ (printing proofs) and also letterpress printing while the rest of the floor was taken up by large printing presses.

The area was reorganised in the 1990s, with the area at the front being used for new offices for Corporate Design and Publishing. There were numerous small rooms off this, which were used for various stores and darkrooms and this was the only part of the building used for traditional photographic/platemaking activities. The computer-to-plate machine that replaced these activities was also located here.

The aforementioned area was separated from the main print floor by partitions.

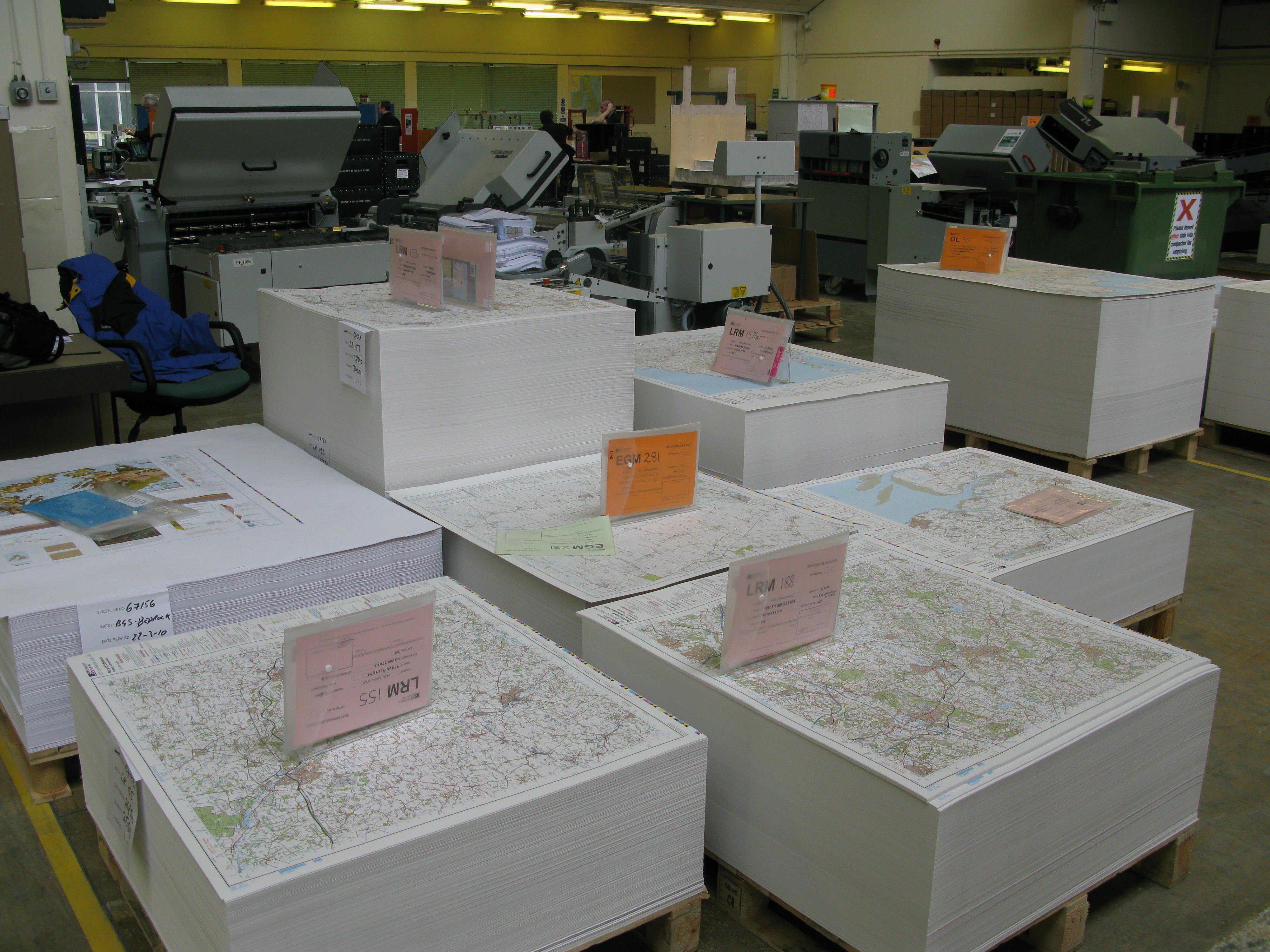

Print Finishing was originally called ‘Map Mounting’ and was located on the ground floor of West Block. At some point after that, this was relocated to the back of the print floor. Print Finishing involves cutting, folding and casing of maps and has a separate page.

Maybush historical Printing

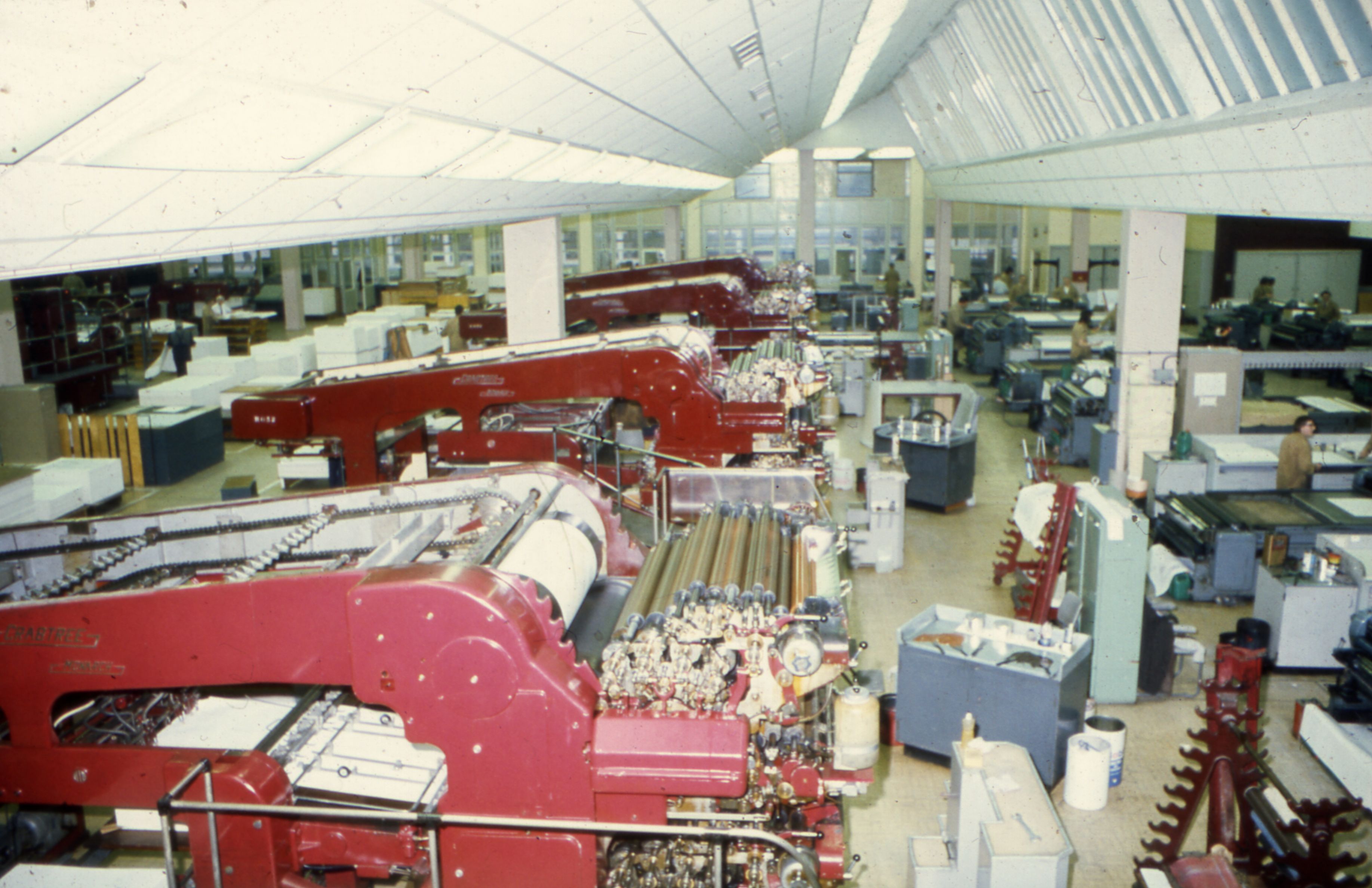

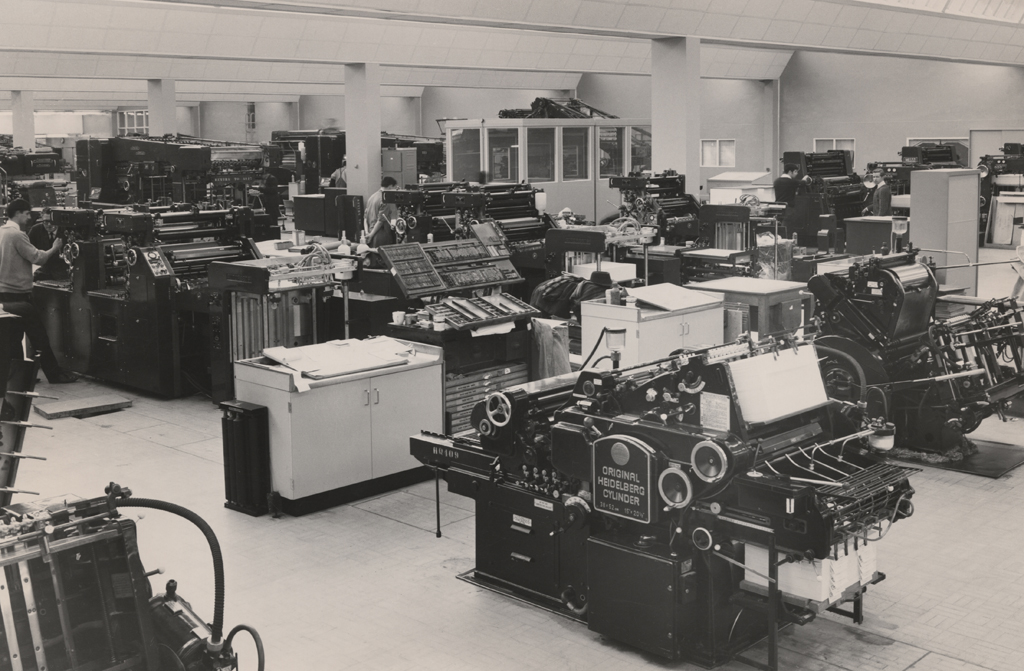

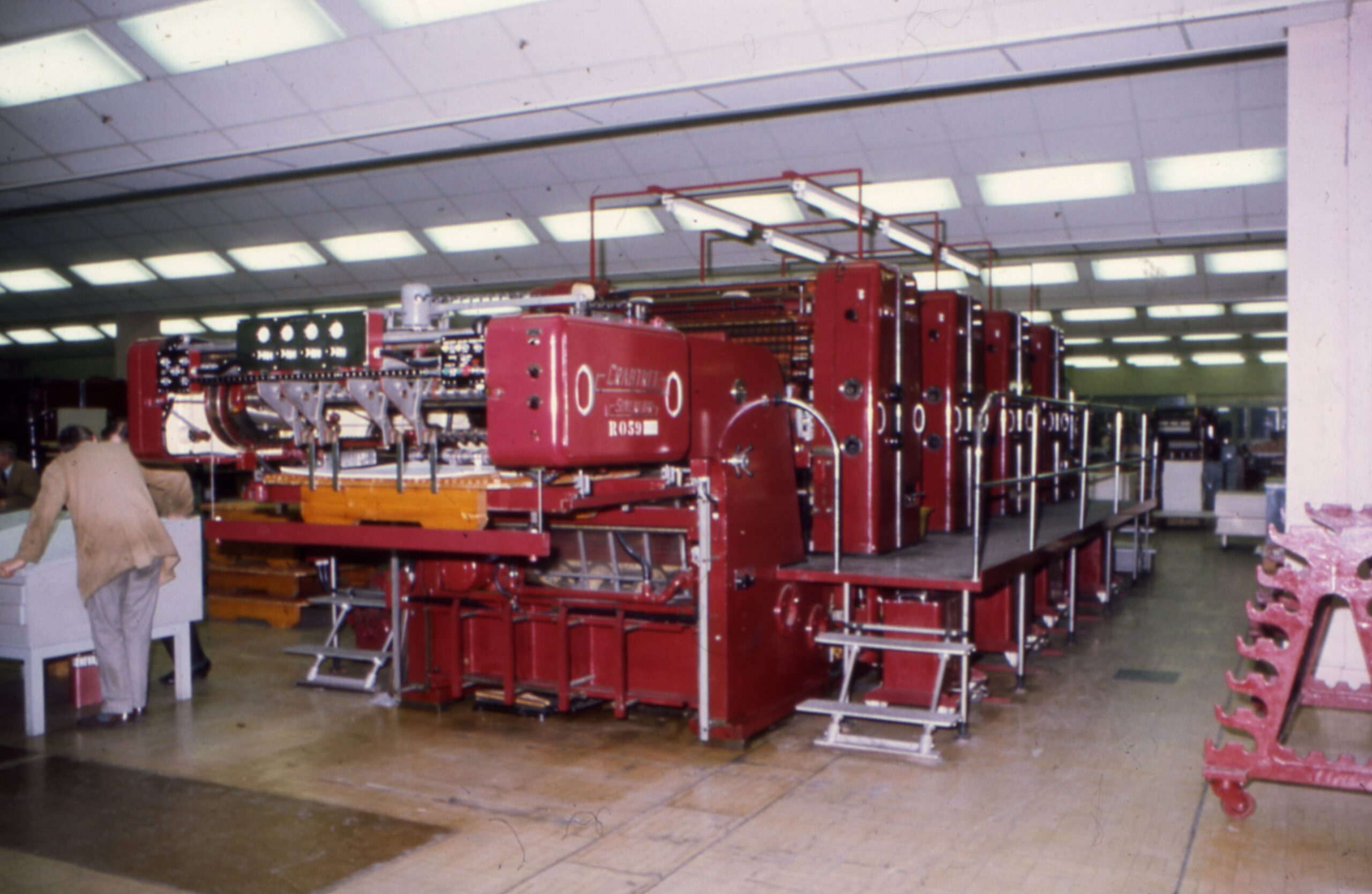

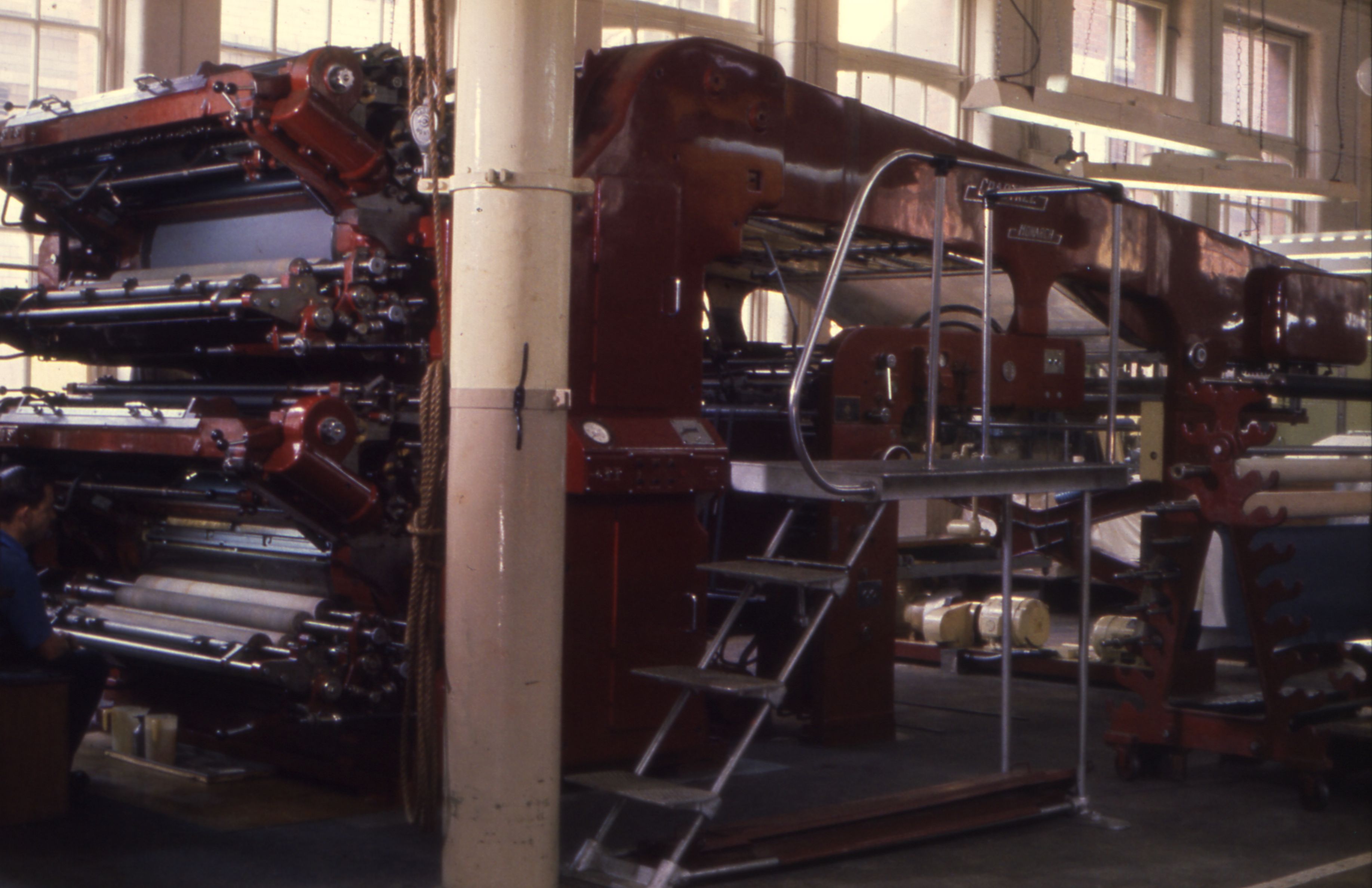

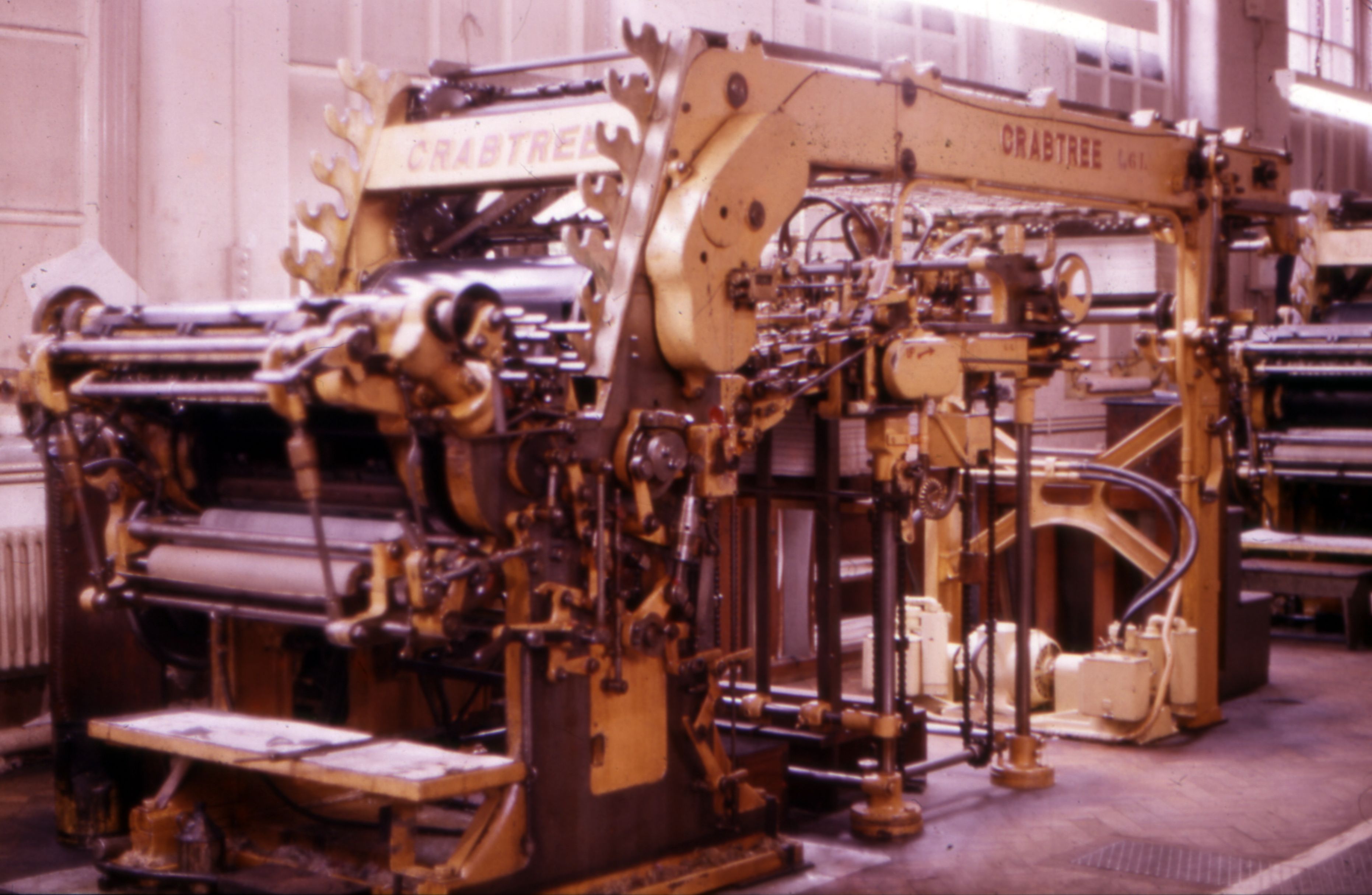

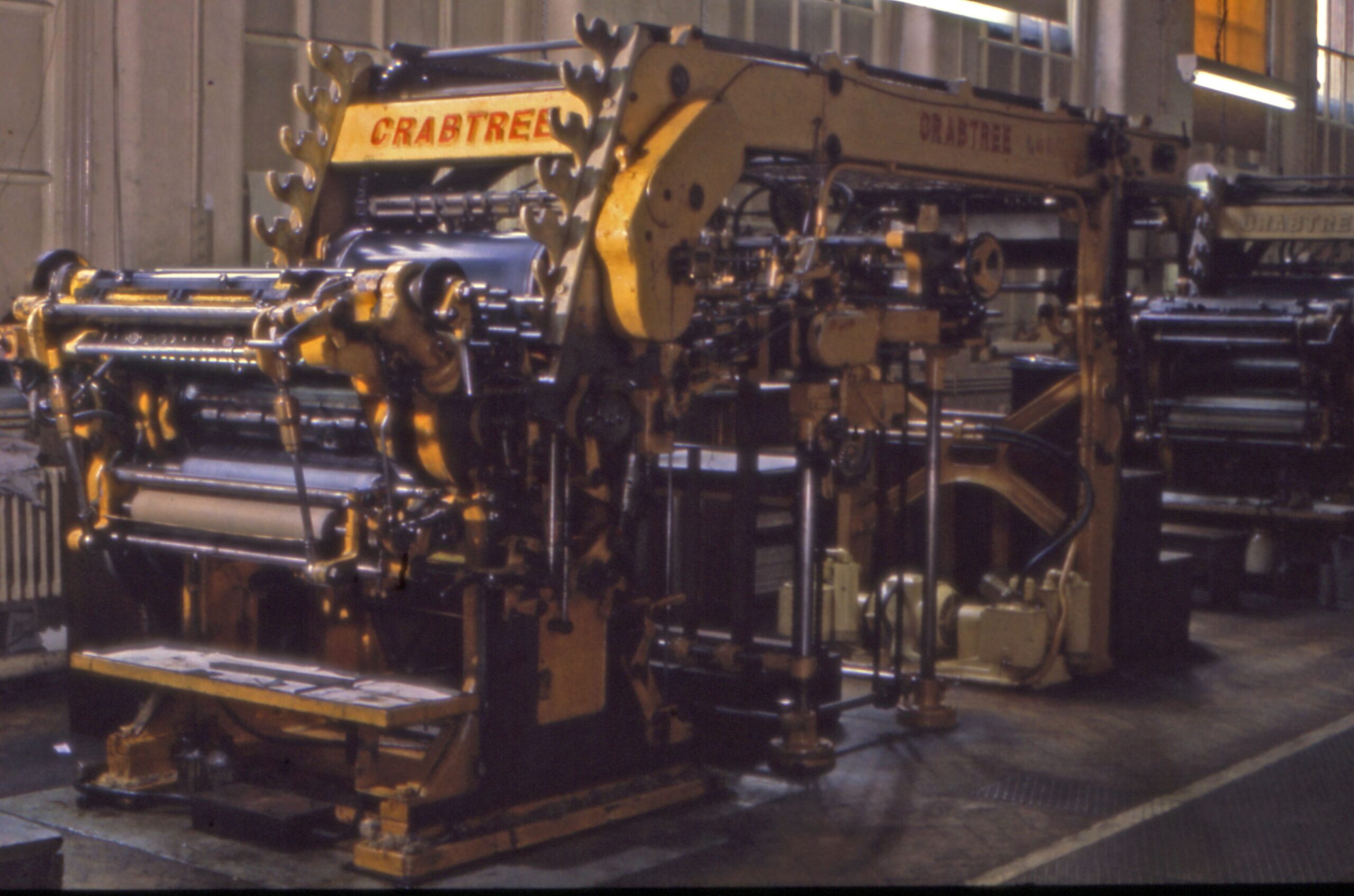

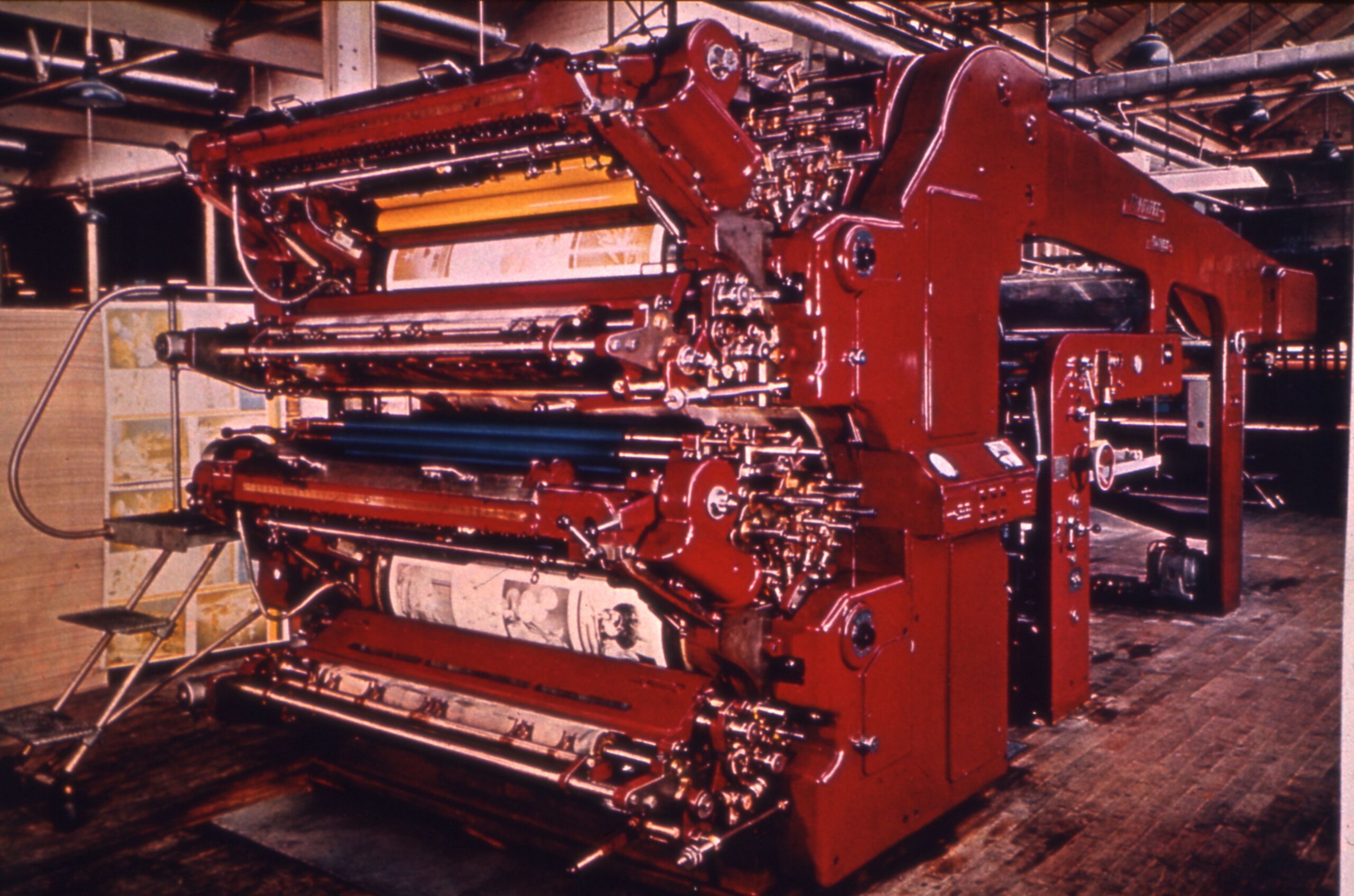

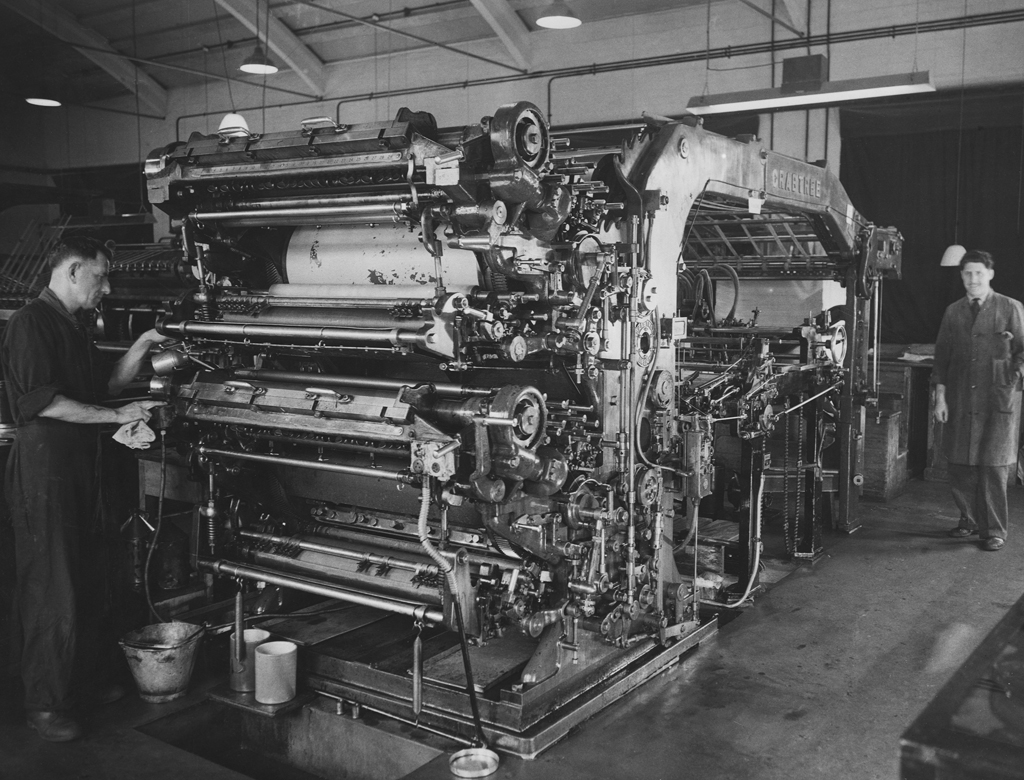

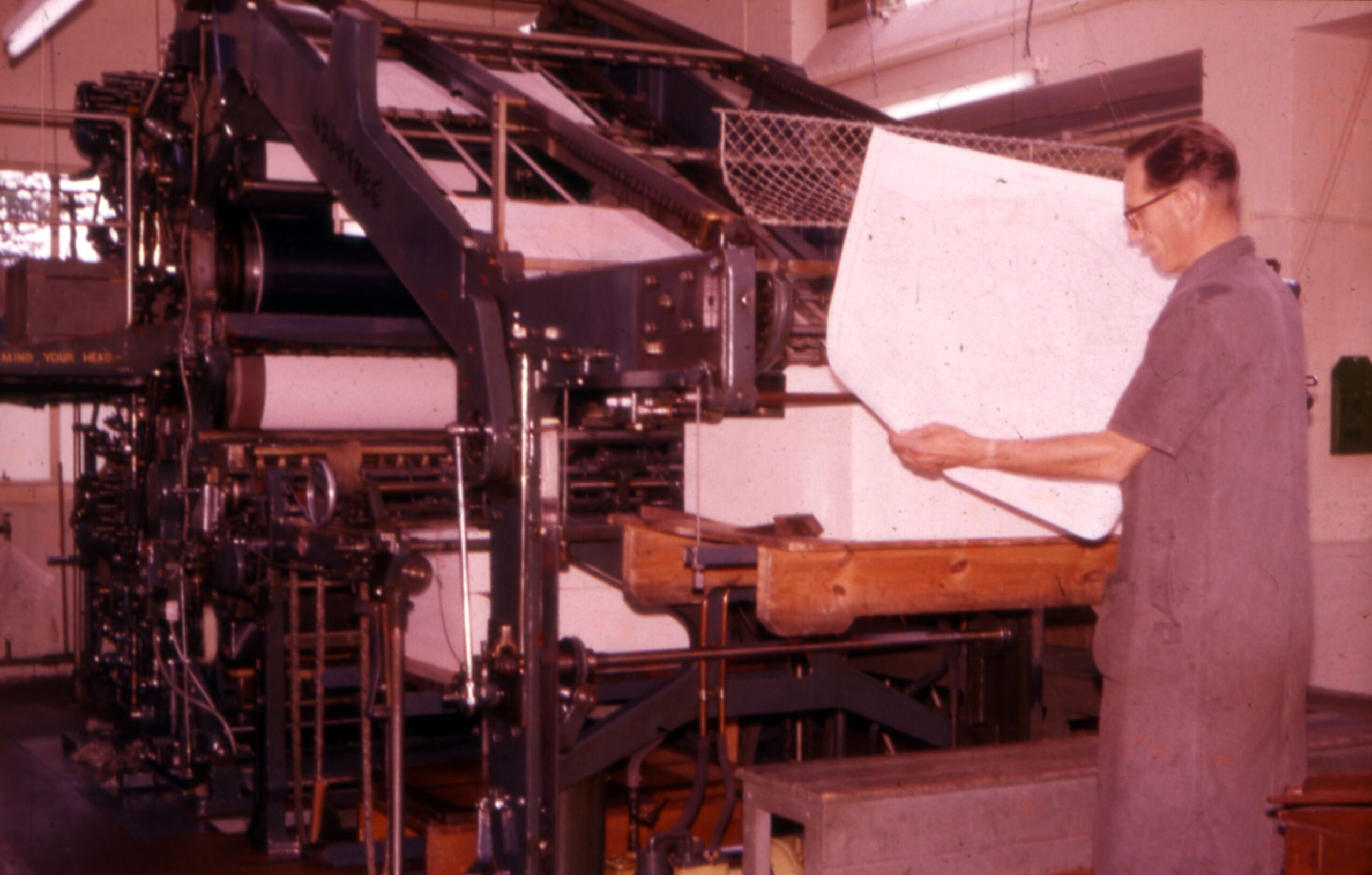

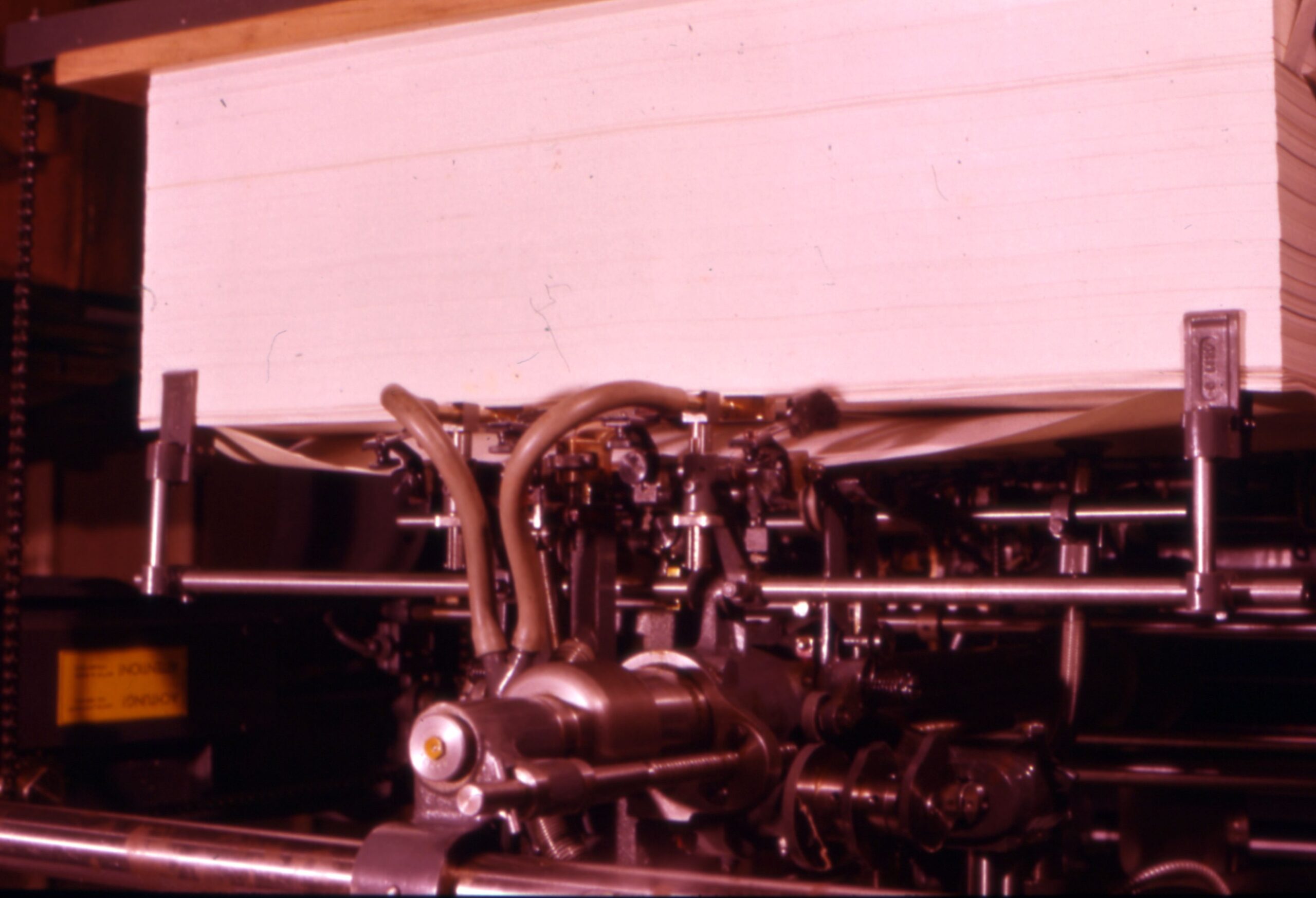

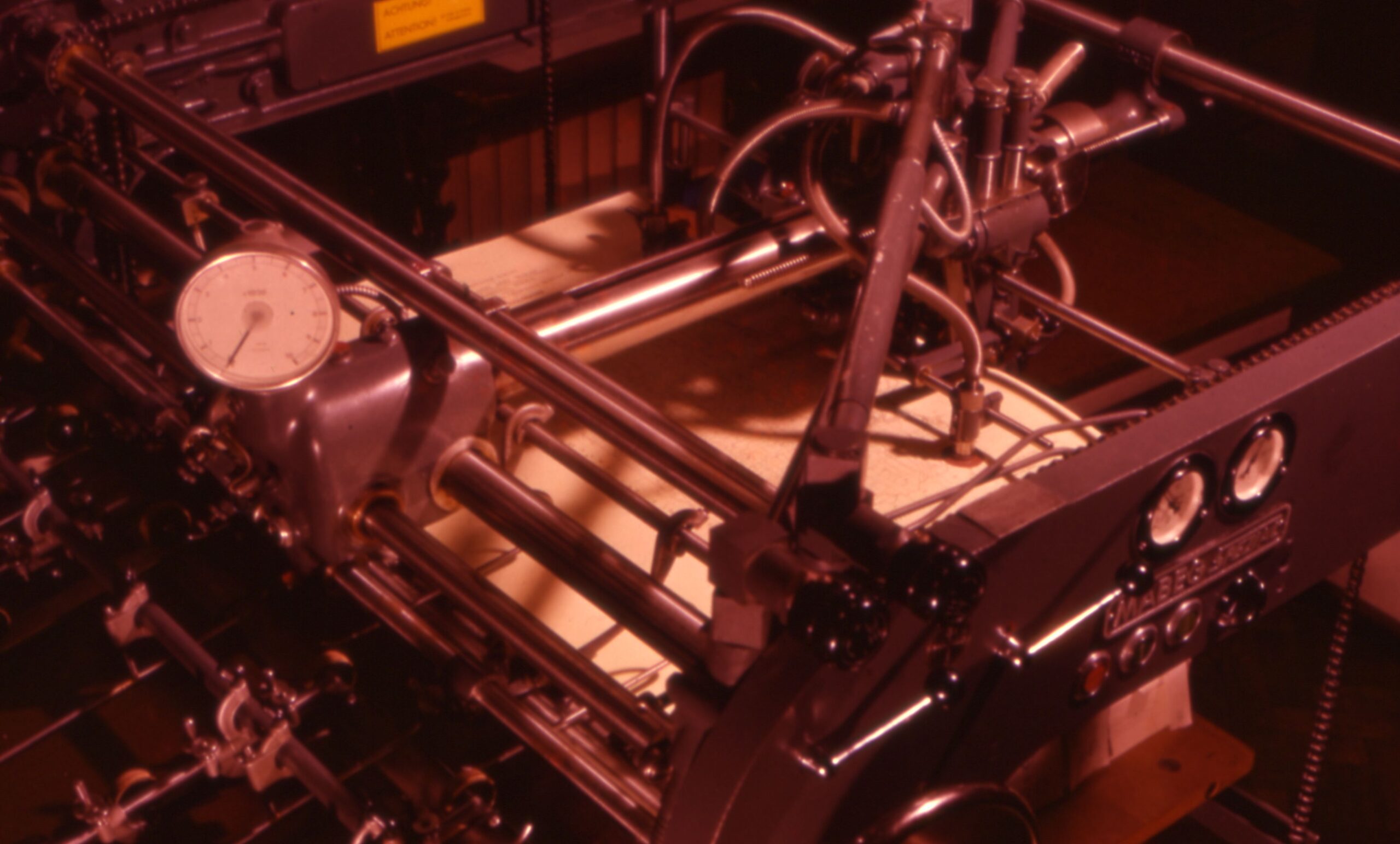

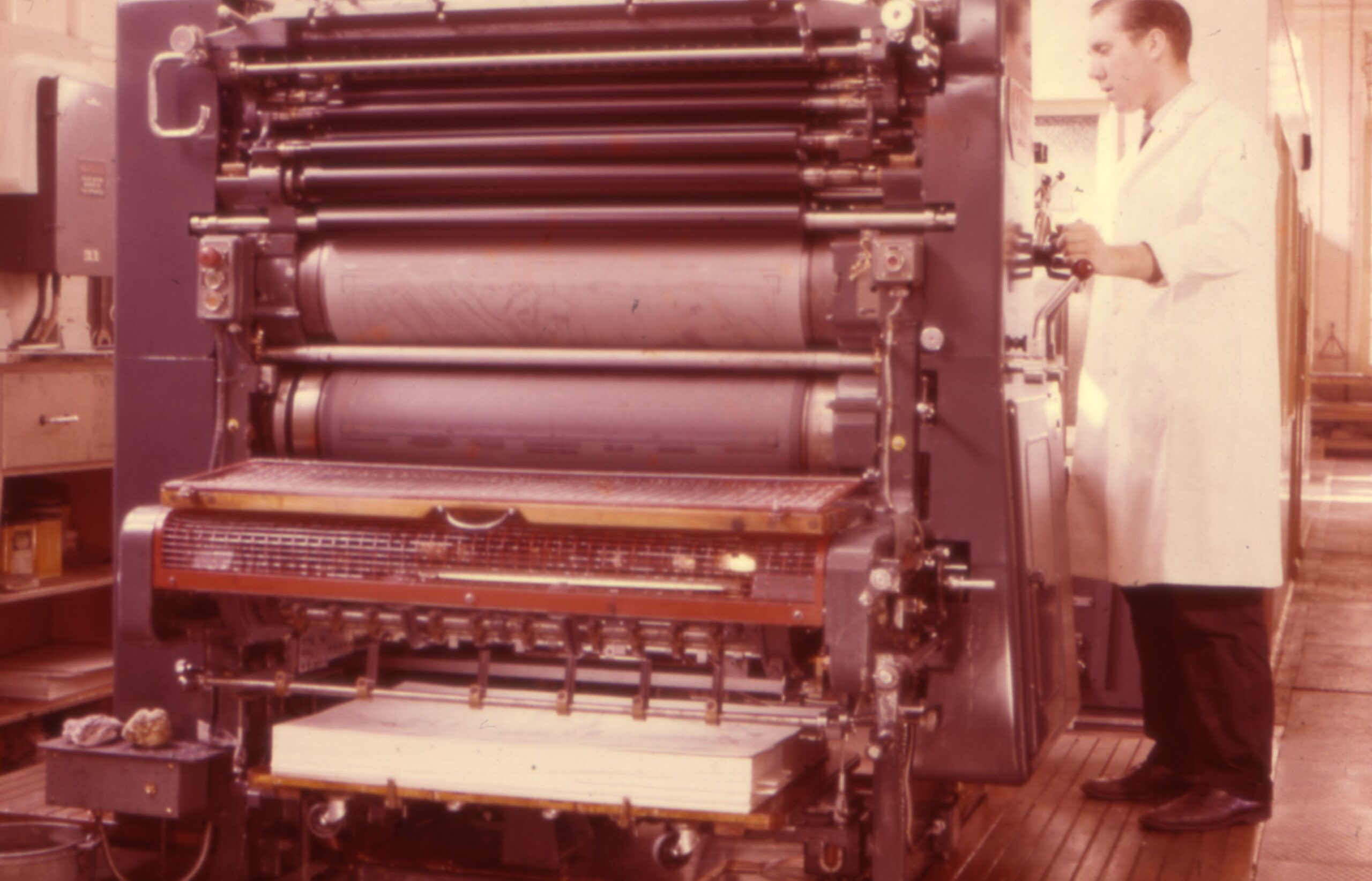

Most of the OS printing presses in the 1960s were made by Crabtree (not to be confused with Crabwood), a British company that is still going strong, and in fact the only British manufacturer of sheet-fed offset machines. Their website has photos and documentation about these stylish historic machines.

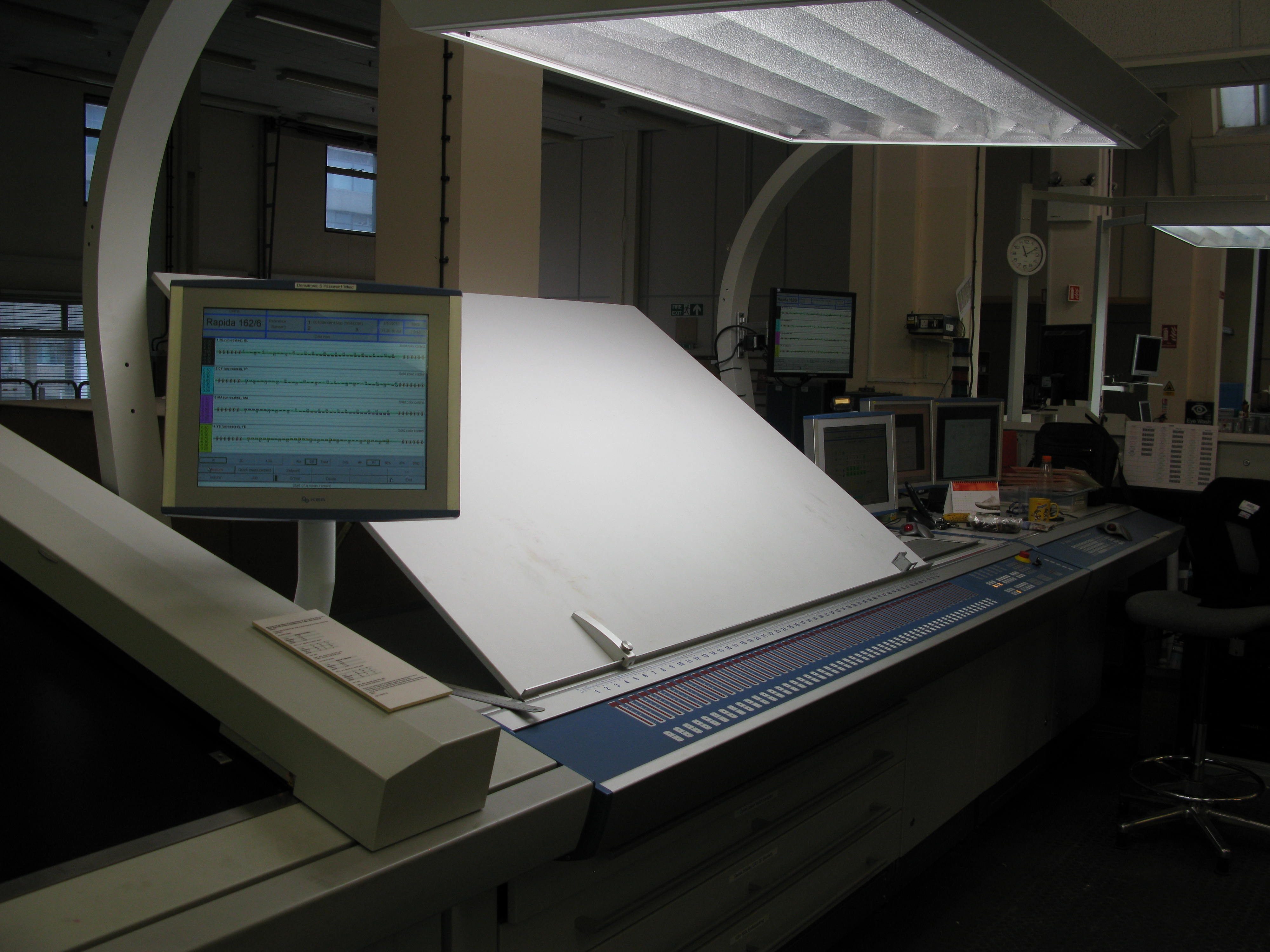

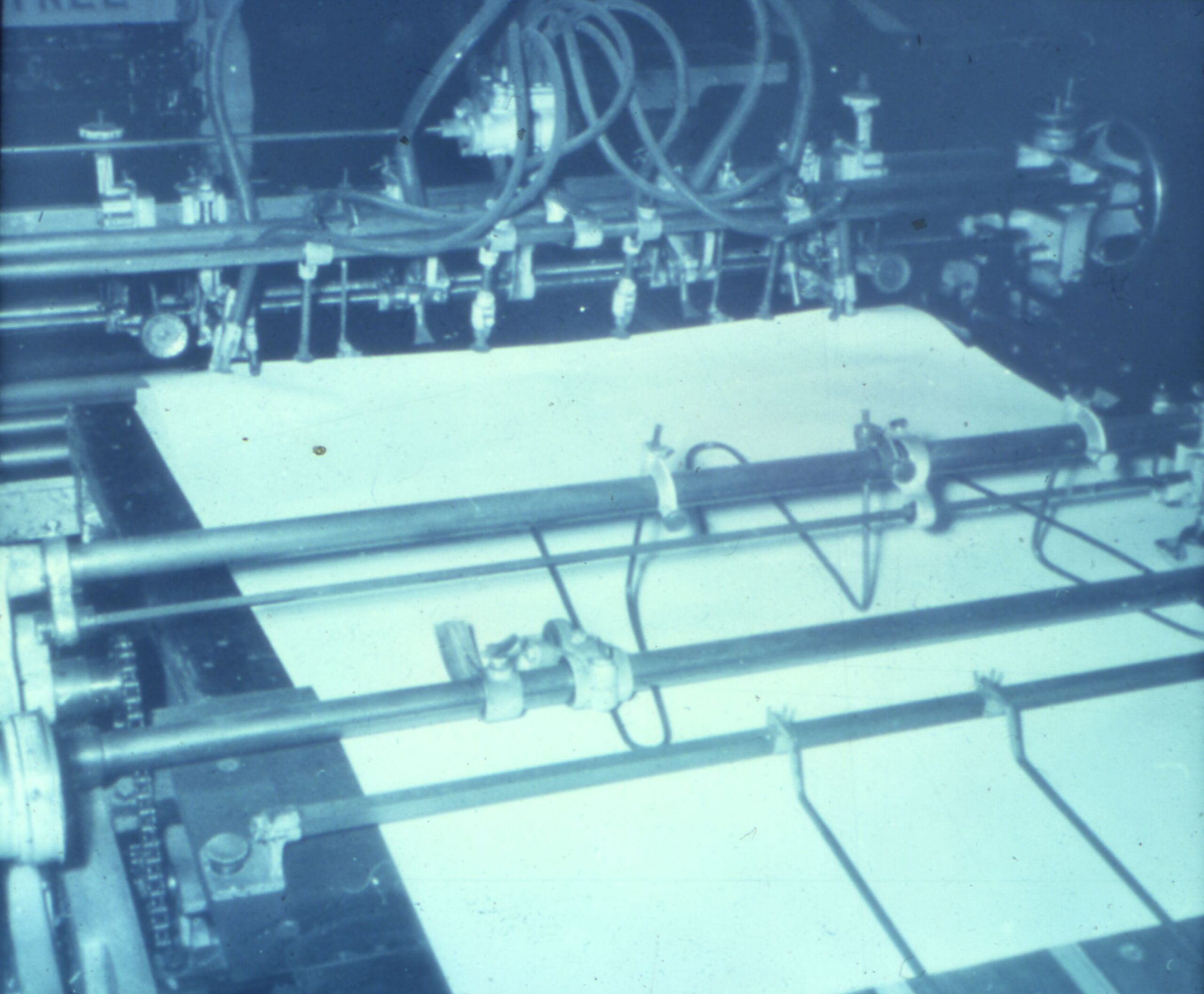

High-level view of one bay of the Print Floor

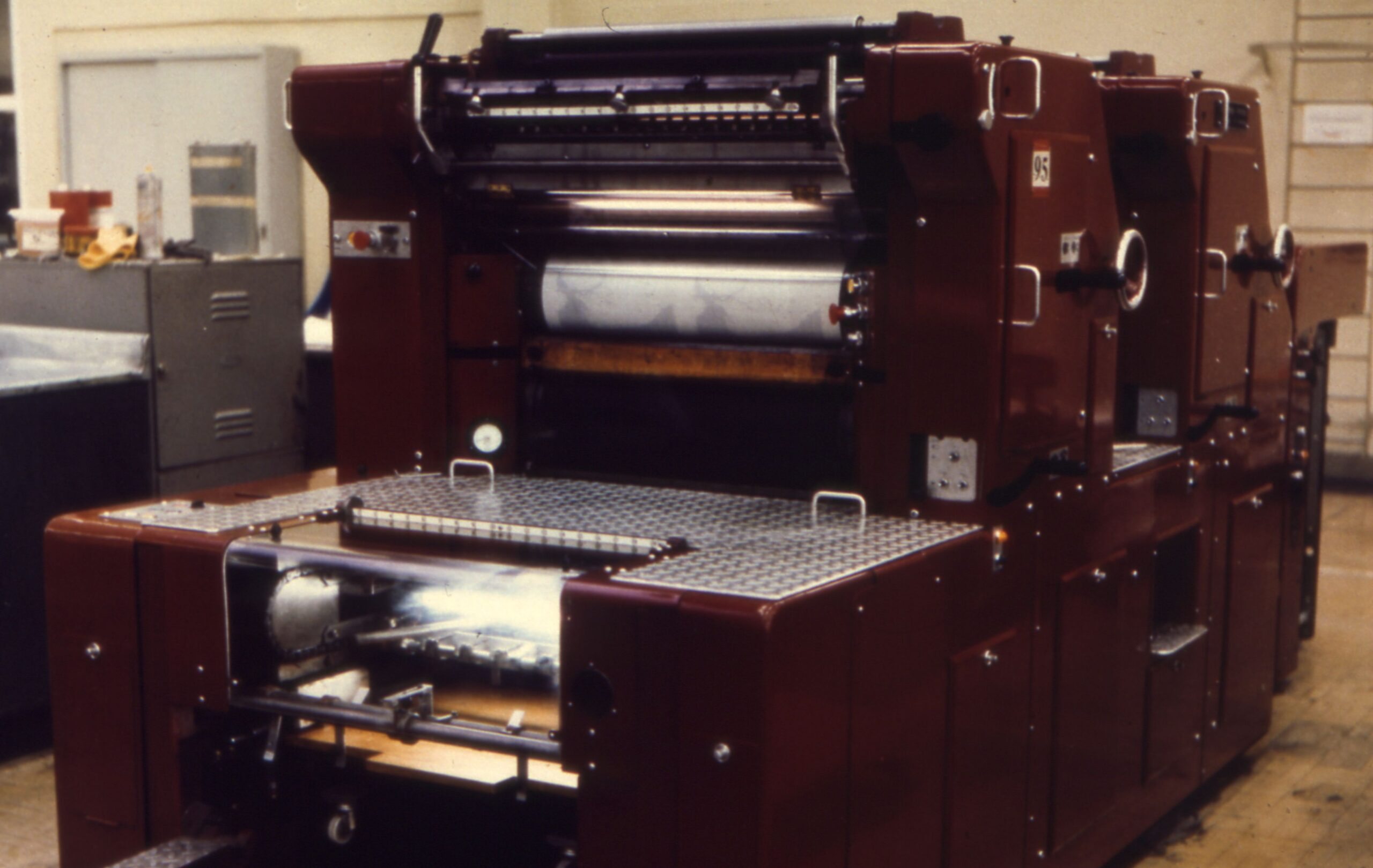

Crabtree Countess printing press

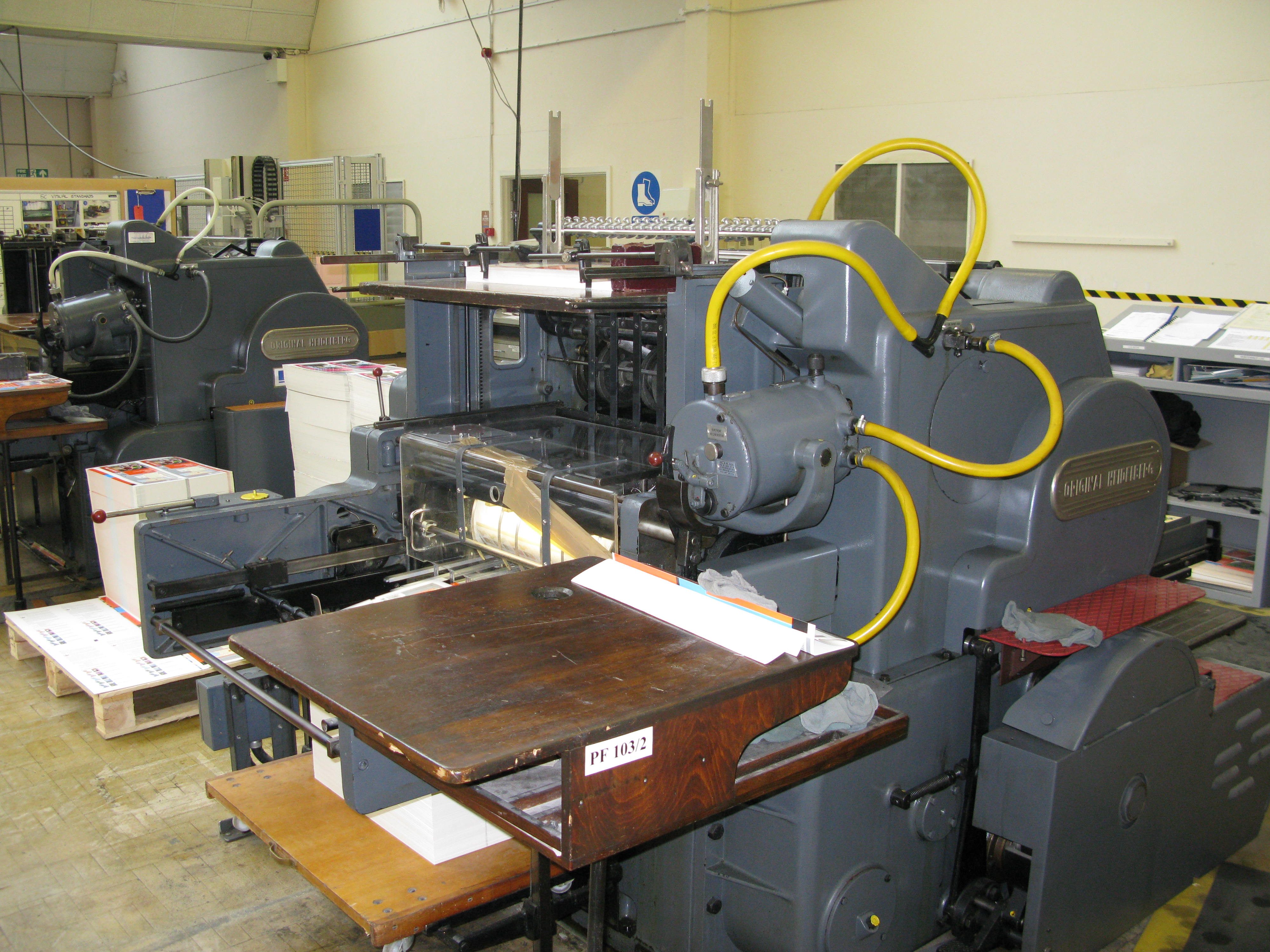

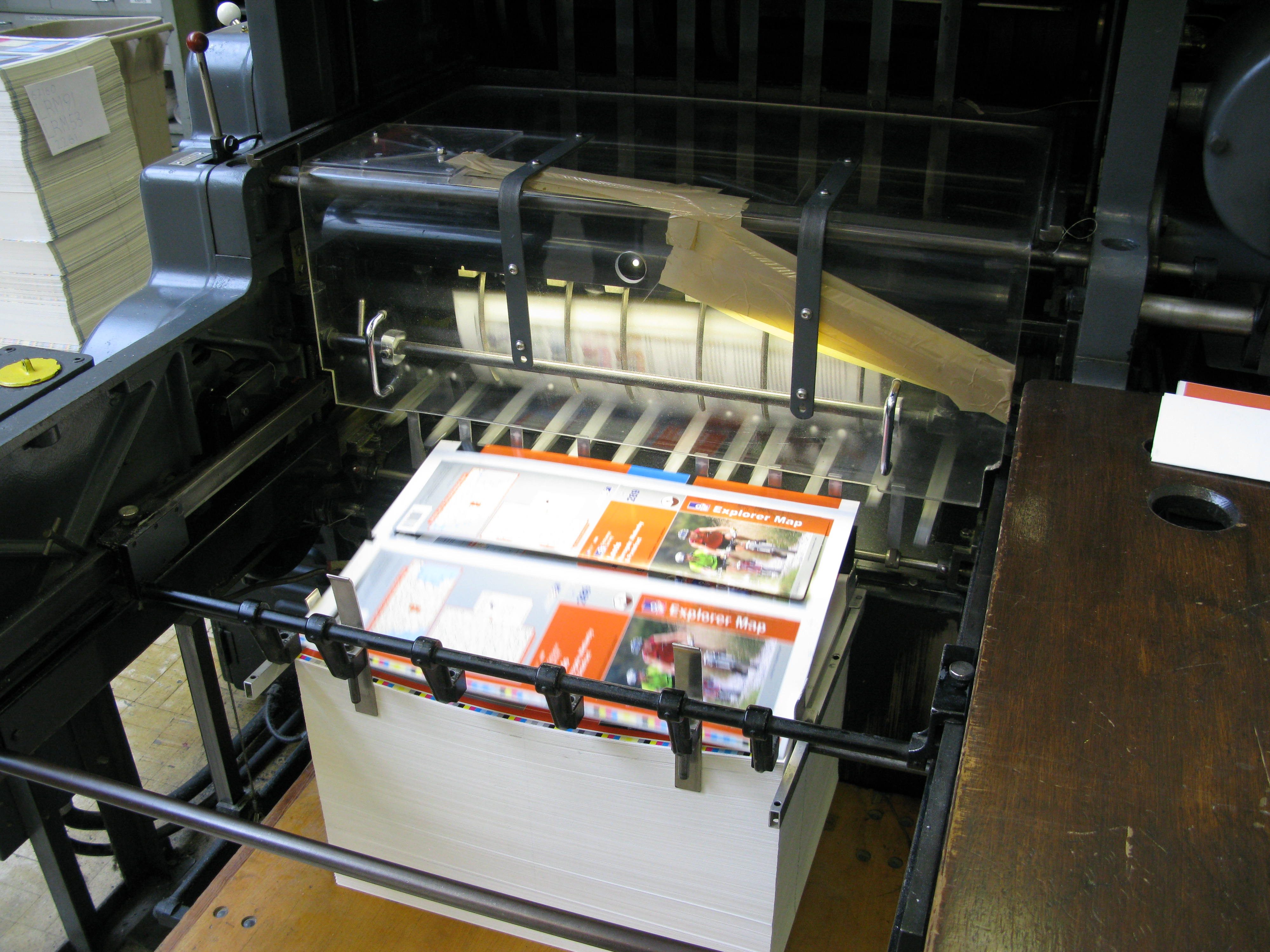

Small printing press at Maybush

Crabtree printing press

Crabtree Sovereign printing press

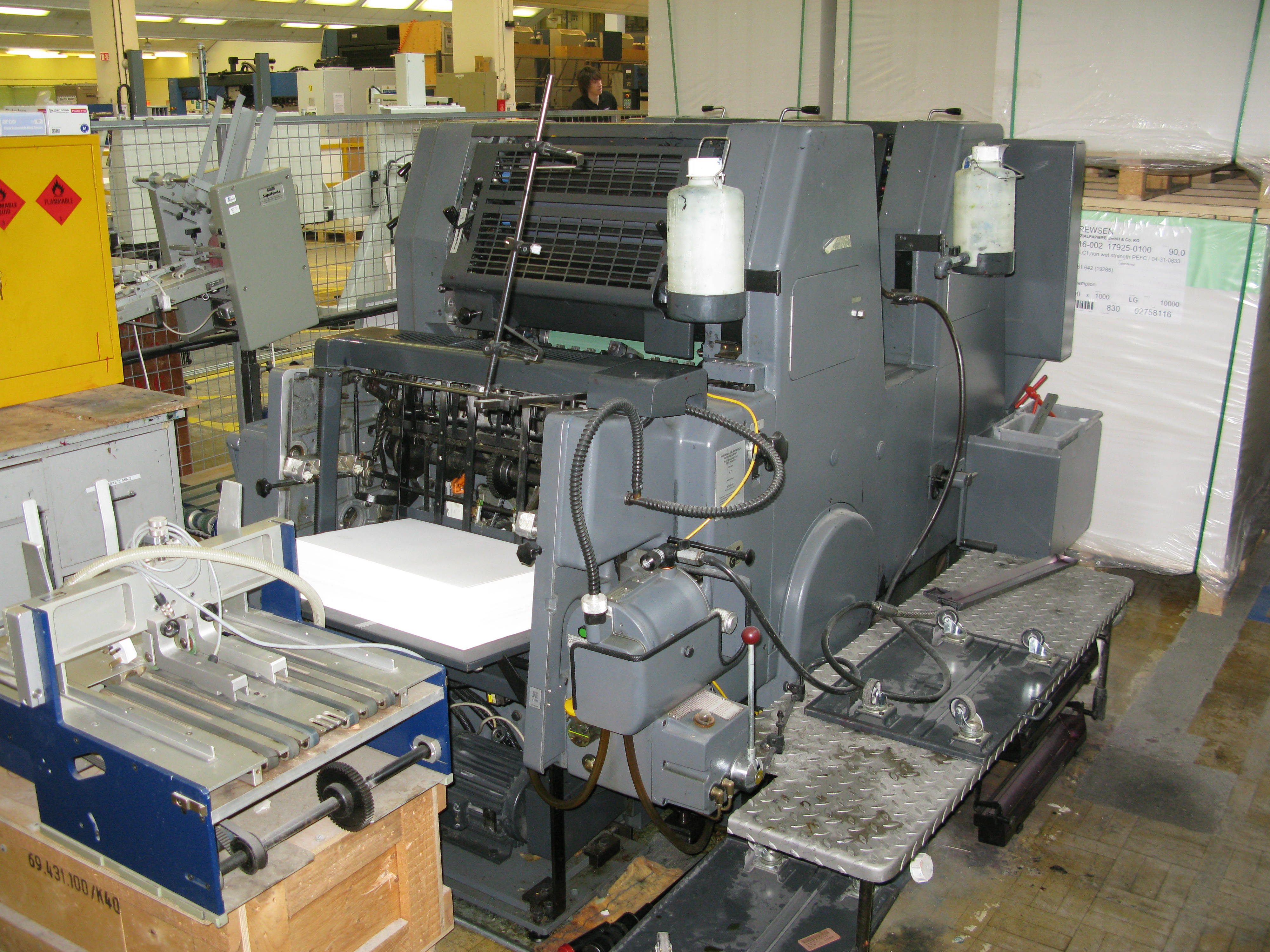

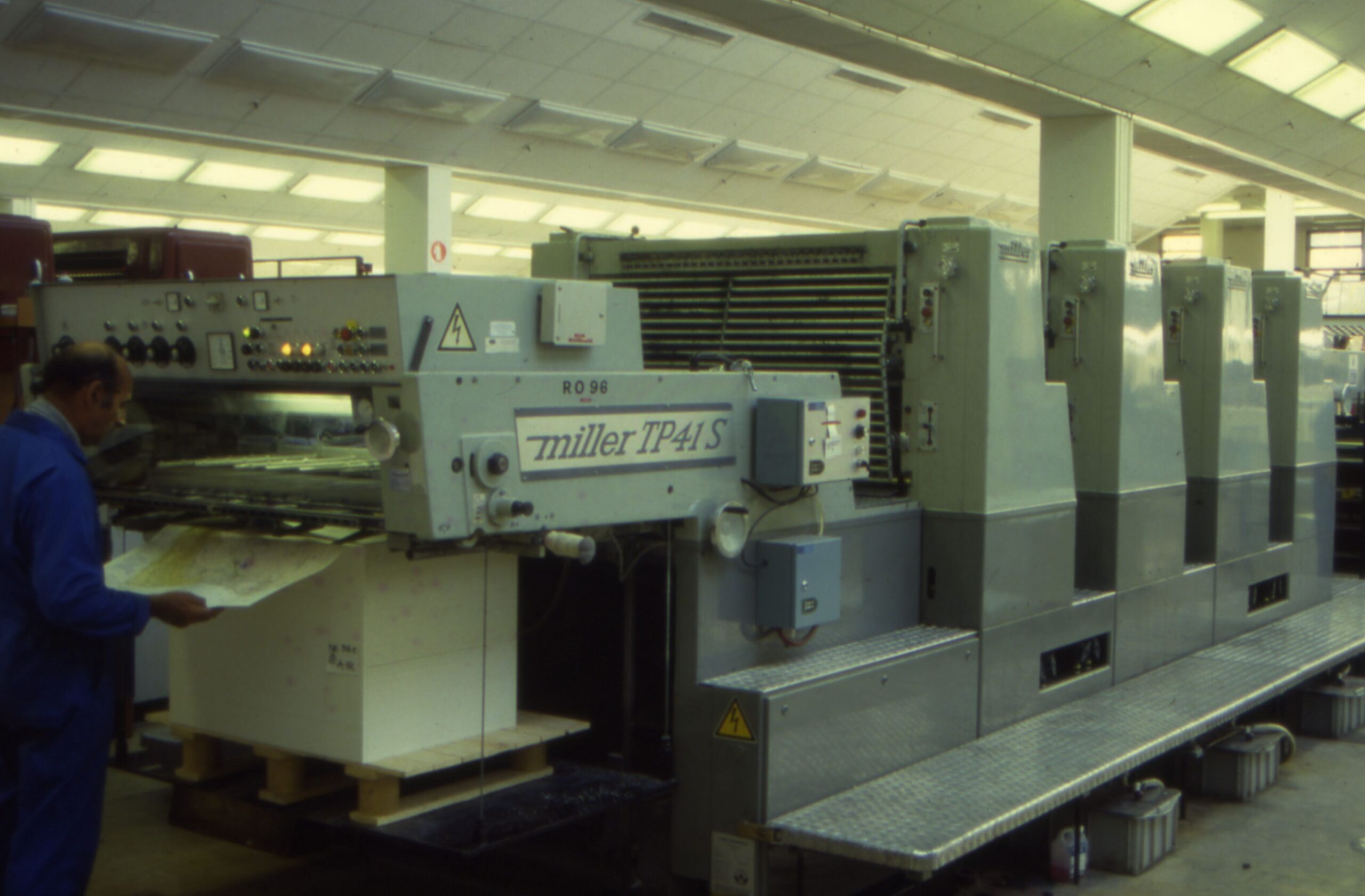

Miller TP41s printing press

Miller TP41s printing press

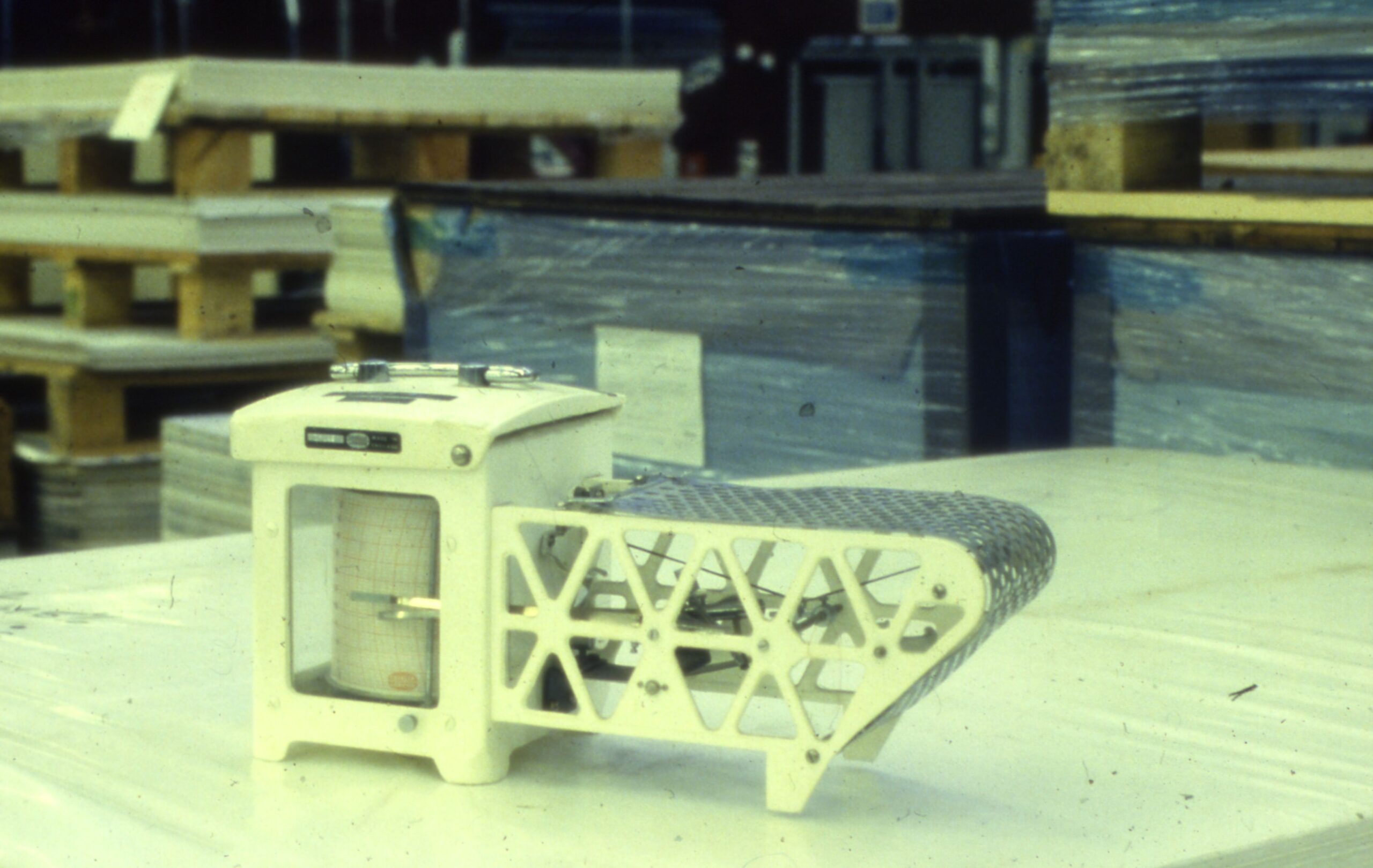

Gretag colour management device

Crabtree Sovereign four-colour printing press, facing SW

High-level view of one bay of the Print Floor

Temperature or humidity sensor/recorder?

Printing machine at front end of the Print Floor

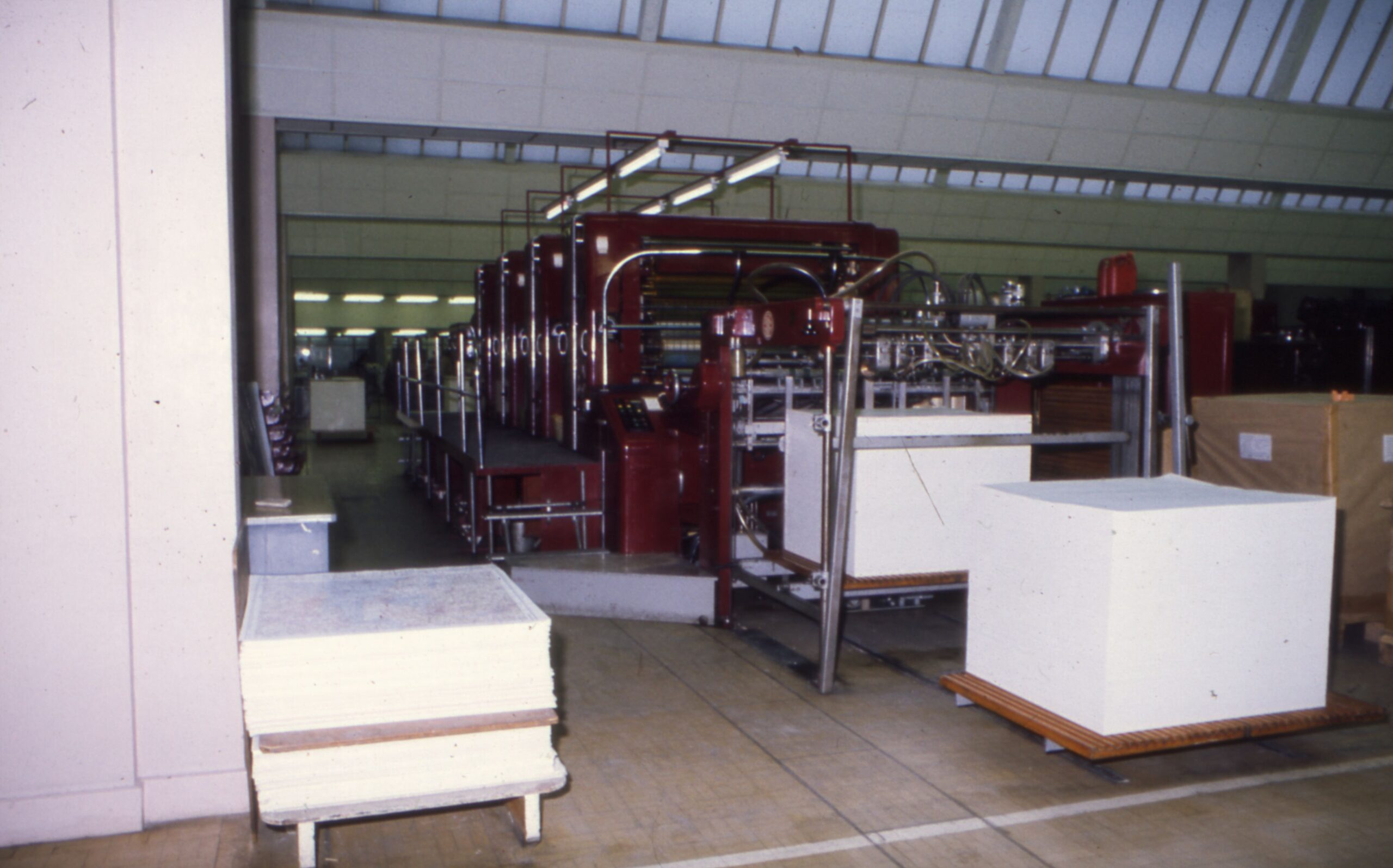

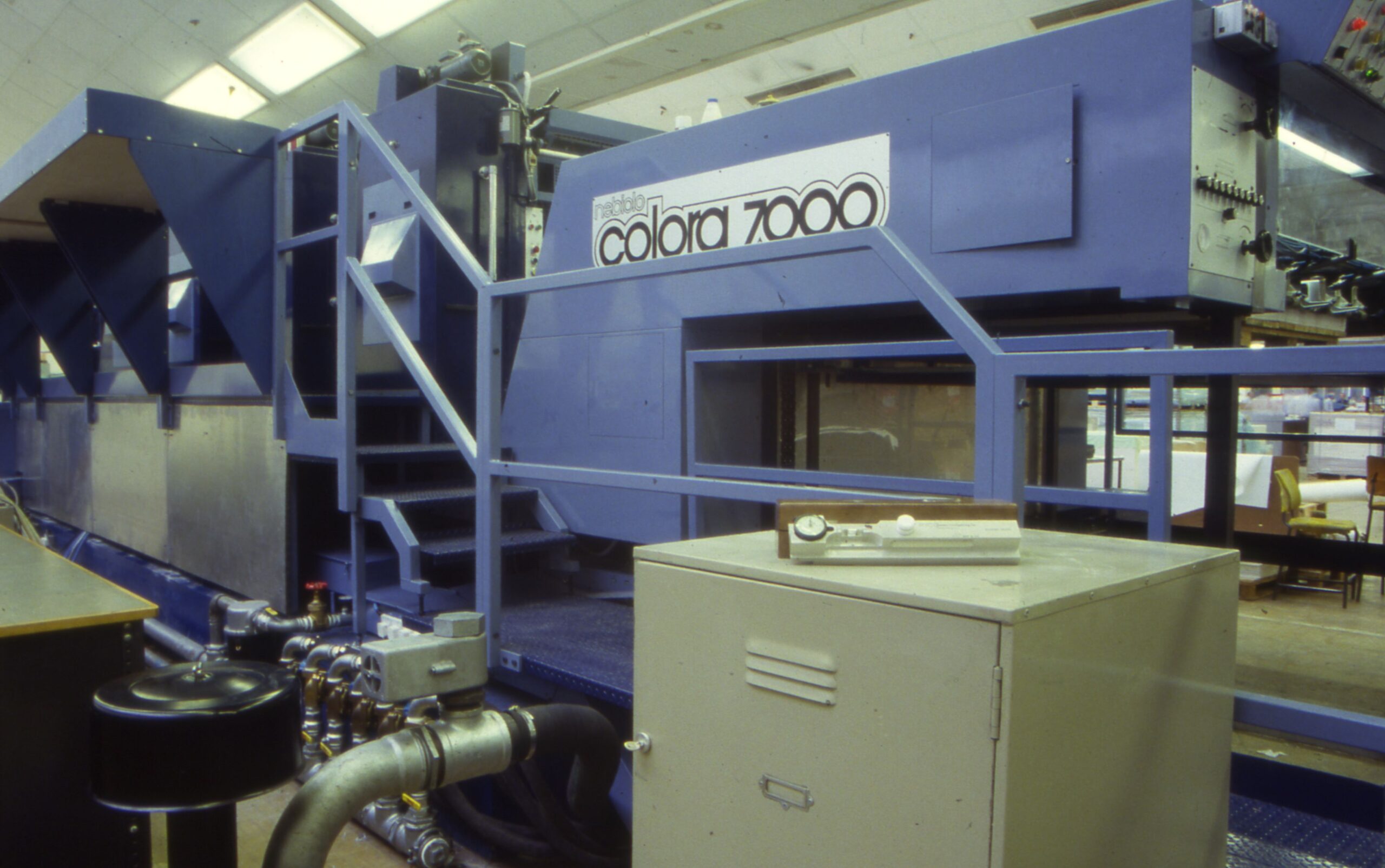

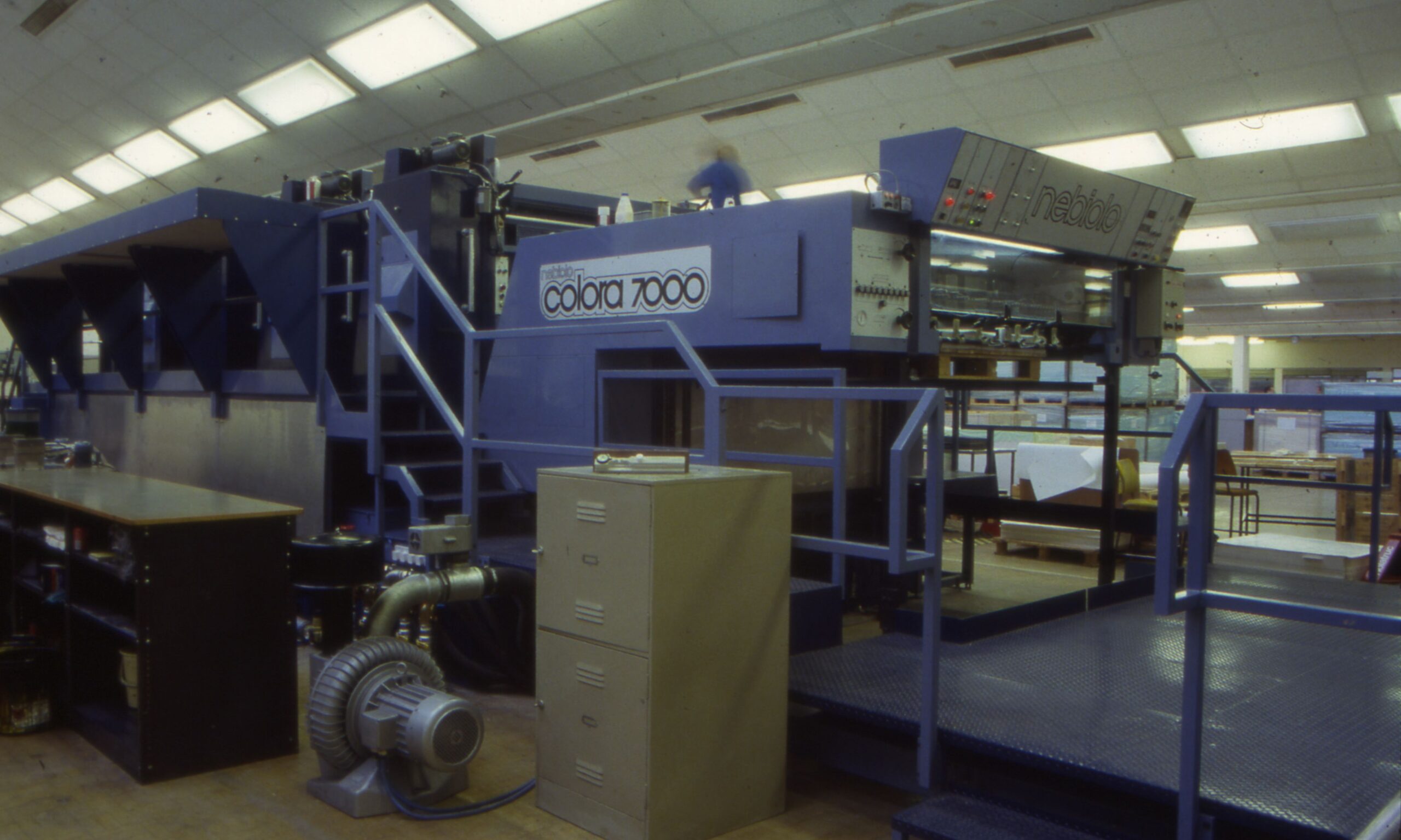

Nebiola Colara 7000 printing press

Nebiola Colara 7000 printing press

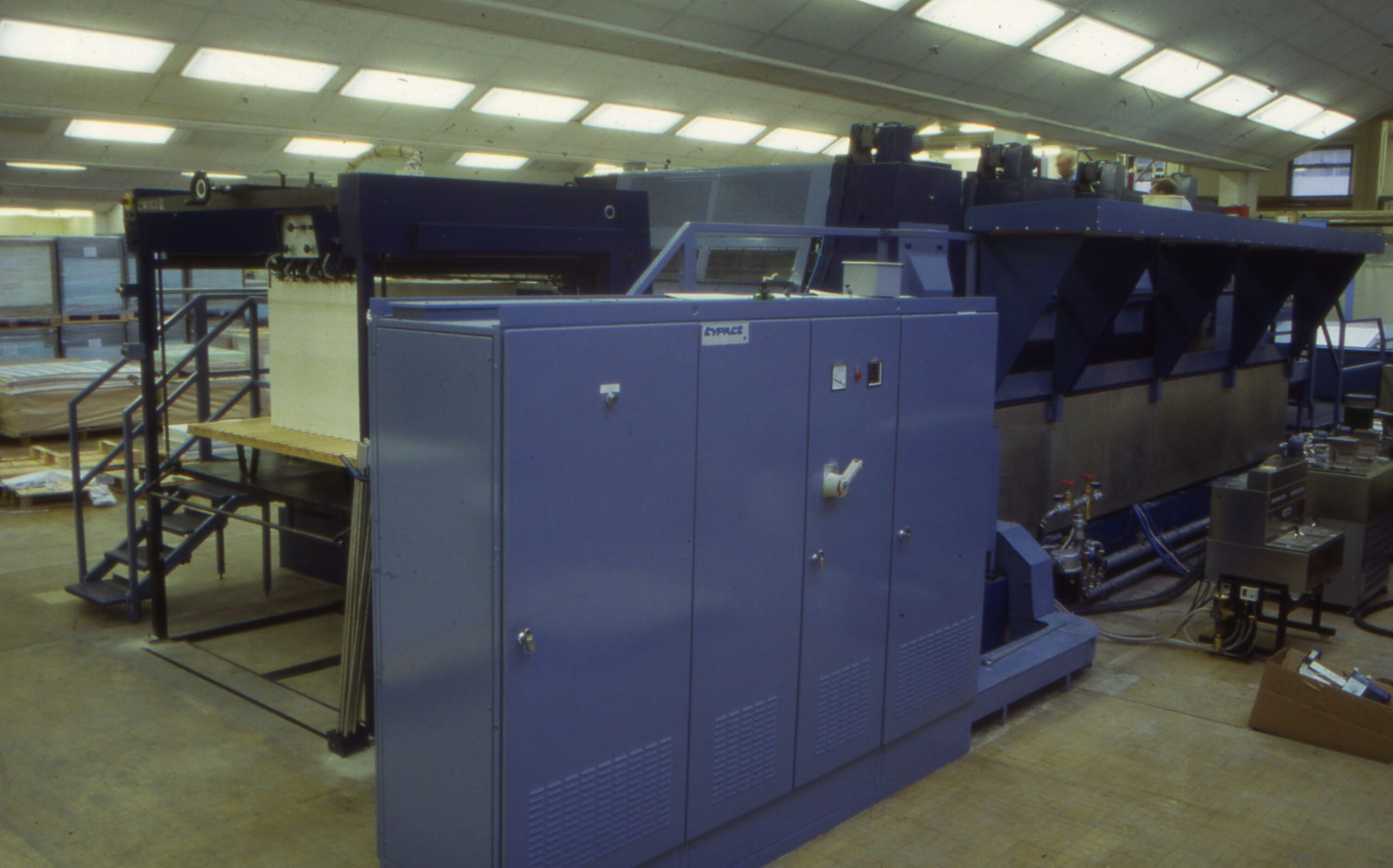

Rear of the Nebiolo printing press?

Nebiolo printing press?

Letterpress – add photos

Printing before Maybush

Before the move to Maybush in 1968-69, printing was carried out in the Romsey Road Block at the OSO Crabwood huts and also at London Road.

Crabtree Monarch printing press at London Road

Crabtree printing press at London Road

Crabtree printing press at London Road, 1950s/60s.

Crabtree printing press, old buildings

Crabtree printing press at Chessington

Historic printing equipment, not Maybush

Historic printing equipment

Historic printing equipment

Historic printing equipment

Small printing press, not at Maybush

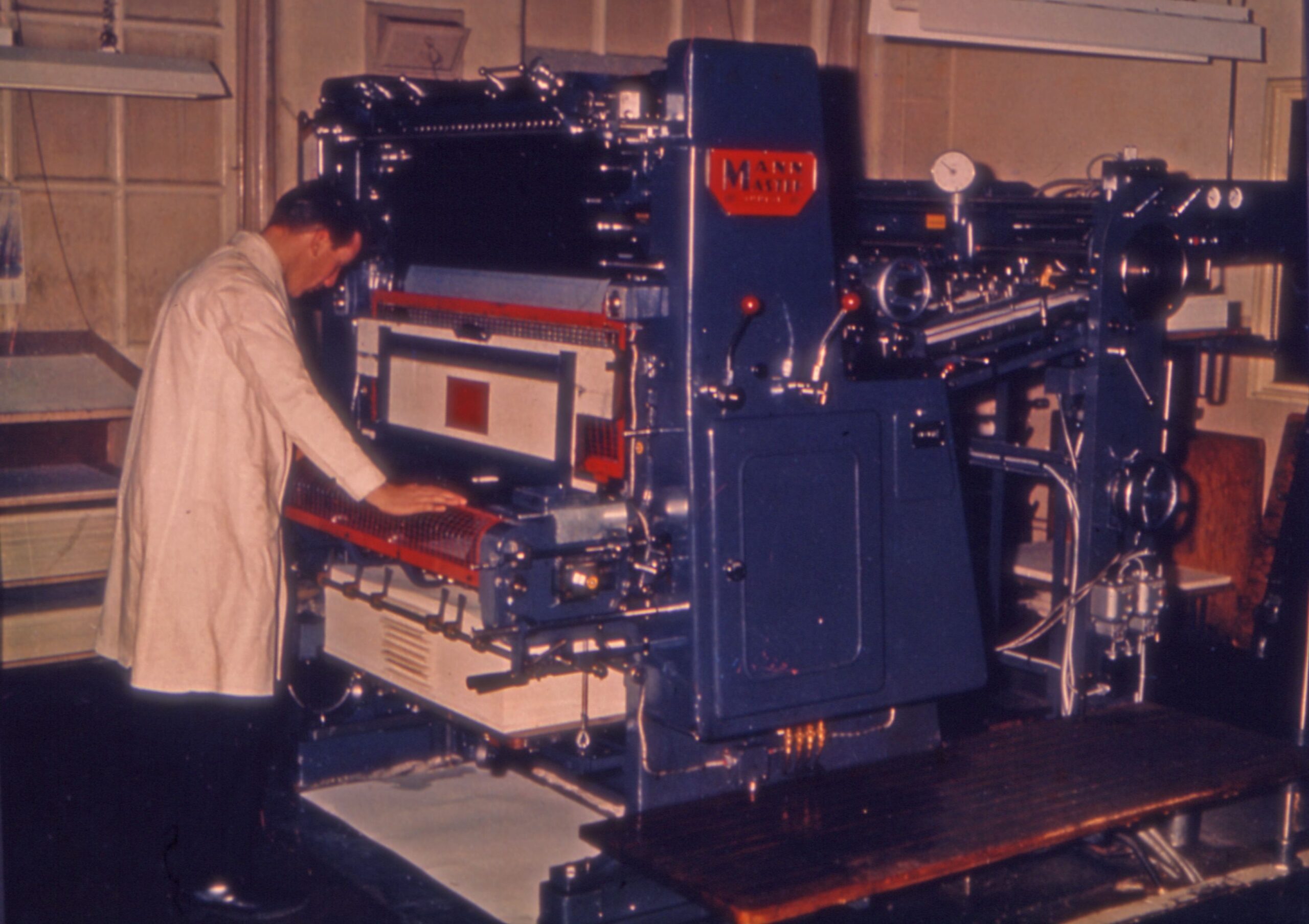

Mann Master printing press

Printing – pre Maybush

Last updated on Friday 29 November 2019 by GaryReggae