The ground floor of the William Roy Building (Central Block) was originally used almost entirely for graphic repro activities. This was divided into two sides by the central spur.

The north western side of the central spur was used as the main Print Floor until Ordnance Survey departed the site and the printing was outsourced in 2010. It housed printing presses, guillotines, folding machines and more.

The SE side of the central spur was originally used for Helio/PLC/platemaking and the Photographic area. This side was converted to the Business Centre in 2000-01 with some smaller offices at the front and a smaller prepress section at the back.

The three-column-bay wide centre spur divided the two sections (B to K cores) and was home to various storerooms for paper, chemicals and other materials with a record archive store above at first floor level (the latter was originally used as another paper store).

The space at ground-floor level was mainly double-height except for the paper stores spur mentioned above and a three-column-space wide strip of space along the front of the building that was originally used as part of the production areas but was later (as of the late 1990s onwards) home to offices at both ground and first floor levels. The double-height production areas both had an impressive concrete shell roof of a barrel-vaulted design with ‘northlight’ type glazing to the north-eastern elevation of the vaults; this brought ample light into the production areas below.

PHOTO OF C064

The Print Floor was still in its original location as of 2010 although most of the machinery had been replaced, with several different presses over the years, to bring it up to the demanding requirements of a modern map production facility. The most recent acquisitions had been a purpose-built guillotine machine, which was one of only a few in the world, a new KBA printing press and an improved computer-to-plate machine.

The print area originally extended right from the back of the building to the front, however the section beneath the front office spur (B-C cores) was fitted out as offices during the 1990s. The Print Floor was originally used for ‘Proving’ (printing proofs) at the front end and the main printing presses in the middle/back end. As a result of a reduction in the demand of paper maps, the back end was used for ‘Map Mounting’; this was later known as print finishing and entailed folding and ‘casing’ (sticking covers to) maps. The Map Mounting section was originally on the ground and first floor of the middle section of West Block.

The Helio and Photographic areas were located where the Business Centre was later built, in the South/East areas of the ground floor. Like the Print floor, this encompassed the large open-plan area covered by the northlight barrel-vaulted shell roofs and also the entire ground floor of the surrounding office spurs – the ground floor of A-B core spur and the ground and 1st floor areas of A-E core spur. The latter was a double-height space but the 1st floor area was just a void containing ventilation ducts. The ground floor Photographic area below had a suspended ceiling and comprised of various small rooms; mainly darkrooms. The windows facing towards the Restaurant were all blacked out.

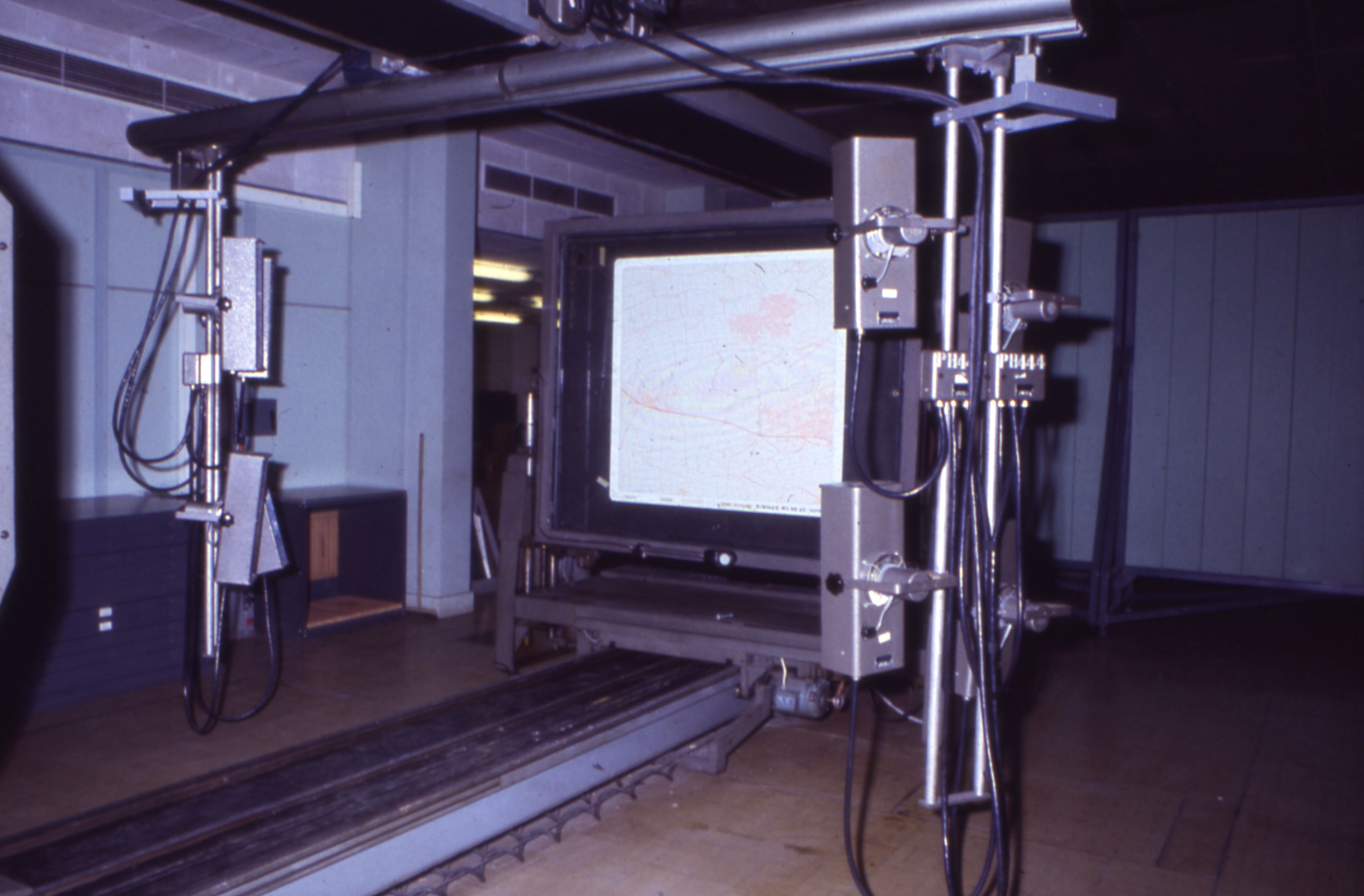

Adjacent to that was a strip of the main northlight roofed area that was partitioned off into three large rooms and various adjacent smaller darkrooms and this is where three large process cameras were located.

The vast majority of the rest of the northlight roofed area was originally designated for Heliozincography (a photographic process that produced printing plates using light but then was later renamed to ‘Photo Litho Composing’. Later on, it was simply known as ‘Graphic Repro A’ (GRA). The print floor was presumably known as GRB.

Granwood flooring

Most of the ground floor, as well as the front part of the 1st of Central Block was floored with ‘Granwood’, a composite material that resembled wood flooring with a basket weave pattern. This was a carefully-chosen material as the architect needed to allow for future replacement of heavy printing equipment etc and constant movement of people and materials, including forklifts and pallet trucks, so something extremely hard-wearing was needed. Granwood blocks are made from sawdust, cement, fillers and soaked in Linseed oil.

Granwood was chosen for flooring in many GPO telephone exchanges, for the reason it was chosen by OS, but its most frequent application was leisure centres and school sports halls. As well as being very difficult to damage, it was also very resistant to fire and flood. After 40 years of use for the OS print floor (literally!) the Granwood didn’t look in that great a condition but it could probably have been sanded and revarnished. Part of the problem was the large number of removable duct covers. The architect was thinking ahead when they added ducts to the repro areas, to allow future flexibility for pipes/power to changes in production equipment/sinks etc but where there are removable parts of the flooring, there is potential for the covers not to be flush with the main floor surface.

Granwood is still going strong today, selling much the same product as used for the OS repro areas so it has stood the test of time!

Last updated on Thursday 23 February 2023 by GaryReggae